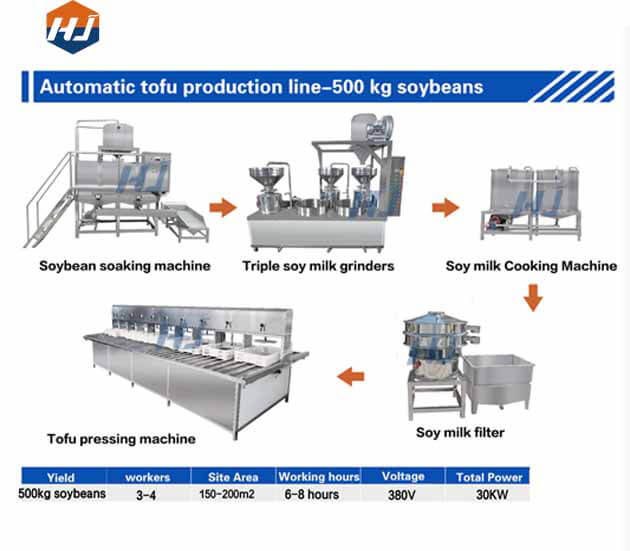

Machine Introduction

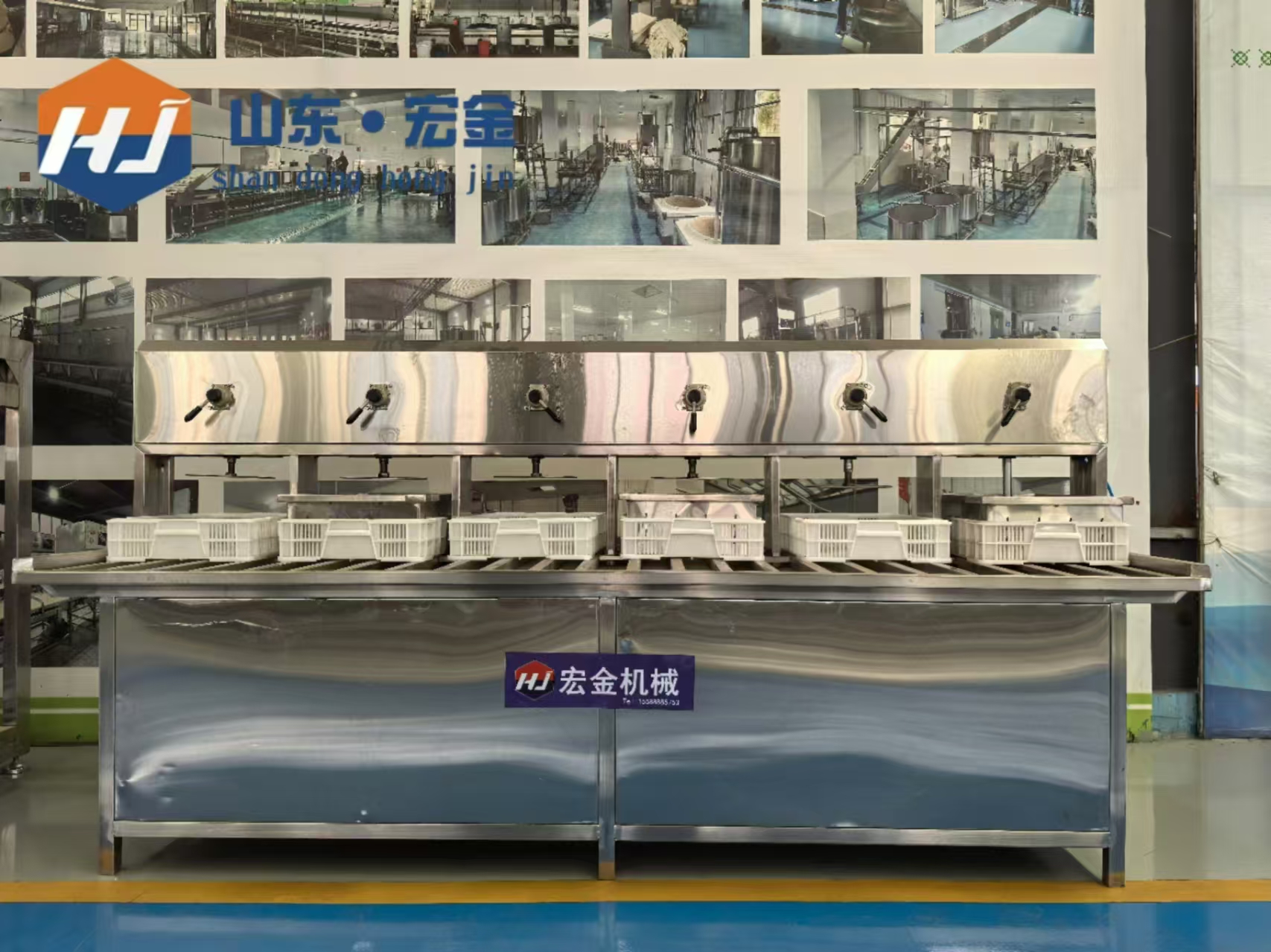

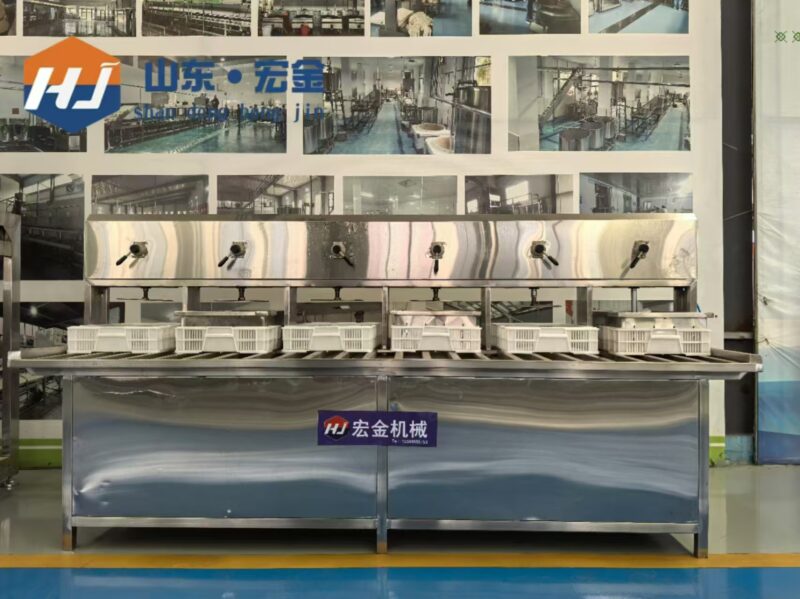

After soybeans are ground, boiled, filtered, and coagulant is added, workers scoop the tofu curd into a tofu pressing basket, cover it with a cloth, put on a lid, and turn on the air compressor to press it. Then the above process is repeated, and the tofu is produced in about ten minutes. Depending on the desired firmness of the tofu, the pressing time can be reduced or extended.

Tofu Forming Process: From Coagulation to Final Pressing

Tofu forming is a critical stage in soy food manufacturing. Proper control of coagulation, curd setting, and pressing directly determines tofu texture, yield, and product consistency. The standard tofu forming process can be divided into three key steps.

1. Addition of Coagulant (Protein Coagulation)

The first step in tofu forming is the controlled addition of a coagulant to cooked soybean milk. The coagulant is added according to a specific ratio and method, causing dissolved soybean proteins to transform from a colloidal state into a gel network.

This step is one of the most important processes in tofu production. The type of coagulant, dosage, mixing method, and temperature all directly affect protein coagulation efficiency, gel strength, and final tofu quality.

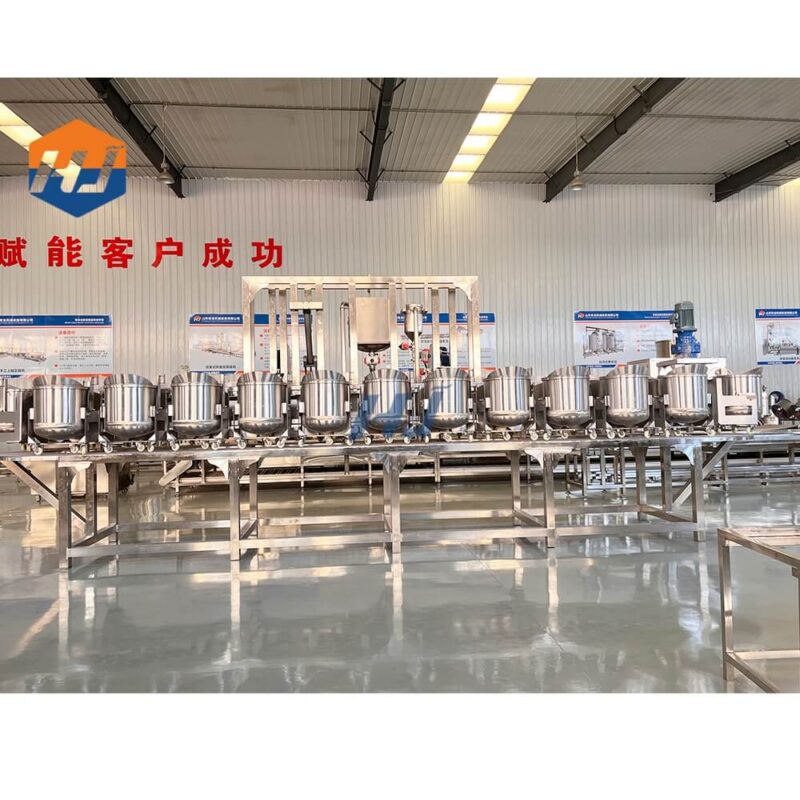

2. Curd Setting and Tofu Curd Formation

After the coagulant addition is completed, protein coagulation continues even though mixing has stopped. At this stage, the protein network structure is still weak and requires a resting period to fully stabilize and complete gel formation.

Typical curd setting times vary depending on the coagulant used:

-

Nigari (magnesium chloride) tofu: approximately 20–25 minutes

-

Gypsum (calcium sulfate) tofu: approximately 30 minutes

During this stage, the process should remain undisturbed. Excessive movement or vibration can damage the forming protein gel network, resulting in internal cracks, weak coagulation, poor structure, and irregular tofu appearance.

3. Pressing and Final Tofu Forming

Once the tofu curd is fully set, it is transferred into forming molds or pressing boxes. Through controlled pressure, excess whey is removed, allowing the tofu curd to bind more closely and form a solid block.

Proper pressing ensures that the tofu achieves the desired moisture content, elasticity, and firmness. The pressure and pressing time must be carefully adjusted according to product type, such as soft tofu, firm tofu, or tofu for further processing.