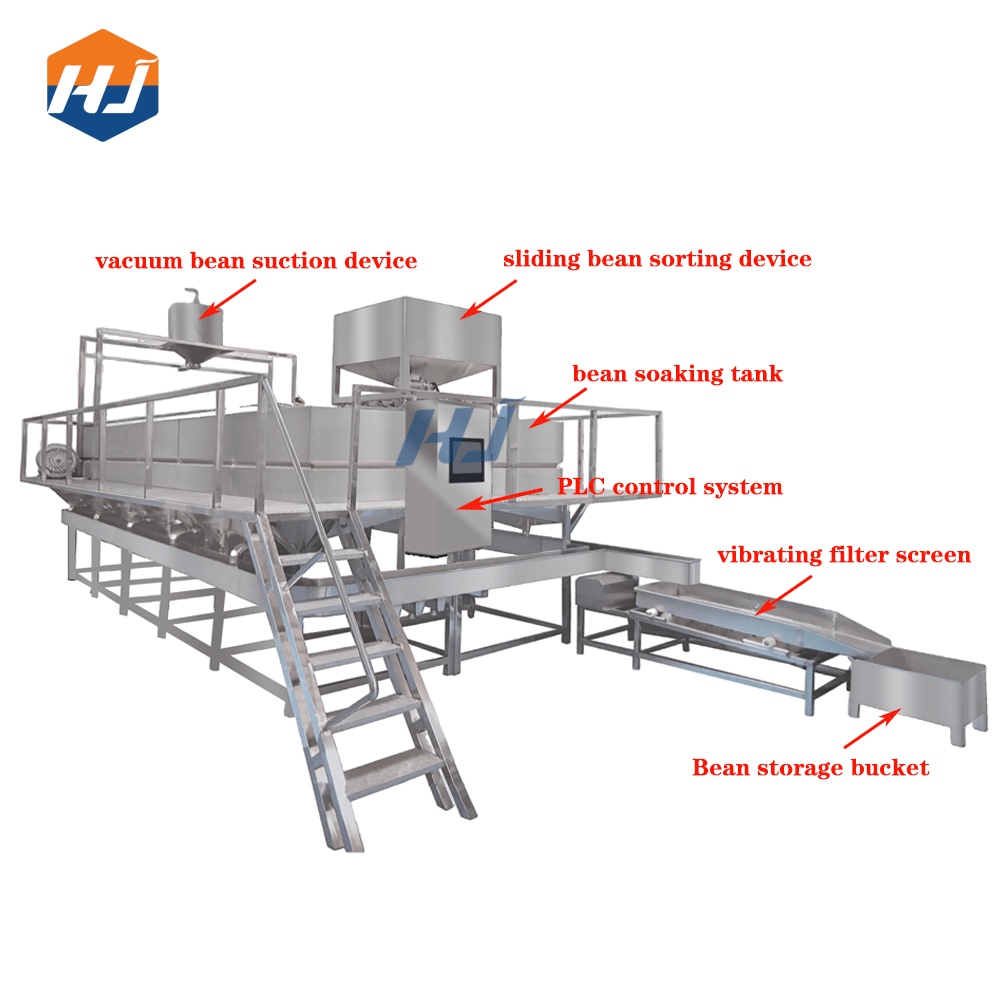

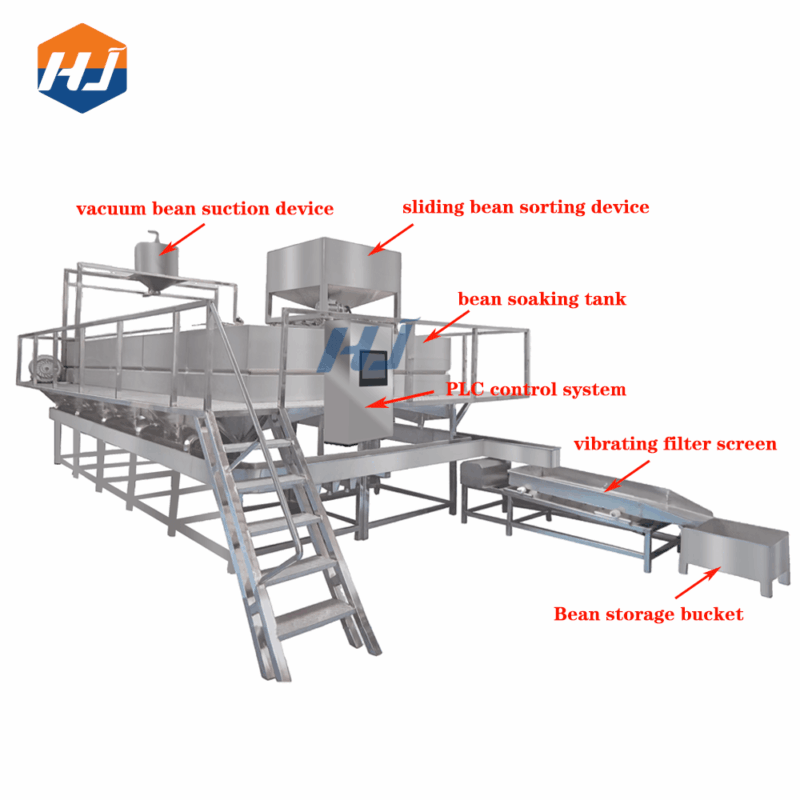

Configuration:

The bean washing and soaking equipment is the first step in the factory’s soybean product manufacturing process. The complete system includes a vacuum bean suction device, storage hopper, sliding bean distribution device, bean distribution track, soaking tank, stainless steel operating platform, stainless steel stairs, PLC automatic control system, automatic water filling system, water level detection device, aeration device, trough filtering device, and vibrating filter screen. The equipment has washing, soaking, draining, and filtering functions. The entire machine is made of stainless steel, except for special parts.

Features:

(1) Automatic feeding – precise vacuum control for soybean suction, eliminating manual handling.

(2) Programmable soaking – adjustable soaking time for optimal results.

(3) Automatic cleaning – intelligent water distribution and rinsing for efficient cleaning and water saving.

(4) Drainage and conveying – the cleaned soybeans are automatically discharged to the next production stage.

Soaking:

This refers to allowing soybeans to fully absorb water. After the protein membrane of the soybean absorbs water and swells, its texture changes from hard to brittle and then soft. In the brittle state, the protein membrane is easily broken when ground. After the protein membrane breaks, the protein can disperse in the water, forming a protein colloid, which is soy milk.

Soybean Soaking Degree:

(1) Appearance of Soybeans

Randomly grab a small amount of soaked soybeans and place them in a container of water. Observe whether the water absorption of the soybeans is appropriate. Soybeans with appropriate water absorption exhibit the following appearance characteristics:

1) The soybean kernels should be fully swollen, and the degree of swelling should be consistent throughout;

2) The surface of the kernels should be bright yellow, round, moist, without wrinkles or sprouts;

3) The soybean skin should be nearly transparent and not detached from the soybean kernels.

4) When a handful of soybeans is grabbed and squeezed tightly, there should be a noticeable “gritty,” “firm,” and rebounding sensation, and a “crunching” sound should be produced. After releasing the grip, the number of soybean skins that fall off should be less than 1/10, and the breakage rate should not exceed 1/15.

(2) Internal Characteristics of Soybeans

Randomly select some soaked soybeans for observation. Soybeans with appropriate water absorption exhibit the following internal characteristics:

1)The center of the soybean should be approximately flat compared to the surrounding area, with a slight concavity.

2)If you can see a narrow line in the center of the soybean that is slightly darker than the surrounding line, it means that the soybean has absorbed about 90% of its water, which is the soaking level required for making soy milk.

3) When you break the soybean with your hand, it will make a very crisp sound, and the broken end will be flat and the edges will be neat.

4) When testing soybean seeds by rubbing them with your hands, the outer skin of properly soaked soybeans is easier to remove. However, separating whole soybeans into two halves is significantly more difficult than removing the outer skin, requiring deliberate force to separate the two halves, accompanied by a slight sound.

(3) Odor of Soybeans

After soaking, soybeans should have a strong “raw” odor. This “raw” odor is a unique aroma resulting from the natural beany smell of soybeans mixed with a slightly earthy, greenish odor characteristic of green plants. There should be no sour or rotten smell. This is a key point in quality control for soaked soybeans.

(4) Moisture Content of Soybeans

The required moisture content of soaked soybeans varies slightly depending on the soybean variety, origin, fat content, growth cycle, and soil conditions, but is generally required to be around 59%. The expansion coefficient of soaked soybeans should be between 1.8 and 2.2 times.

(5) pH Value of Soaking Water

The pH value of the soaking water should be ≥ 6.5, and should not be lower. The water color should be slightly yellow or pale yellow.

If the following conditions occur, it indicates that the soybeans have not been soaked sufficiently: the outer skin of the soybeans still has obvious wrinkles, and the surface of the soybeans is not bright, round, or moist enough. The soybean kernels should have a deep indentation of more than one-third of their interior, the same color as before soaking, contrasting sharply with the pale yellow of the surrounding soaked soybeans, with clear boundaries; the soybeans should not break easily, only showing some bending and deformation; the soaking water should be clear, only slightly yellowish-brown.

If the following conditions are observed, it indicates over-soaking of the soybeans: the soaking water is nearly yellowish-brown, has a noticeable sour smell, and some foam may appear. When a handful of soybeans is squeezed tightly, it feels mushy, soft, slippery, and sticky, lacking elasticity, without the sound of soybeans rubbing together, and not “gritty” to the touch; when released, most of the soybean skin will easily peel off, and the soybean kernels will separate along with it. The separated kernels are flat and loose, their color being a pale yellow, predominantly pale white; the edges of the soybean kernels appear to have been soaked in water, turning whitish, and they can be easily broken without the crisp sound of steel.

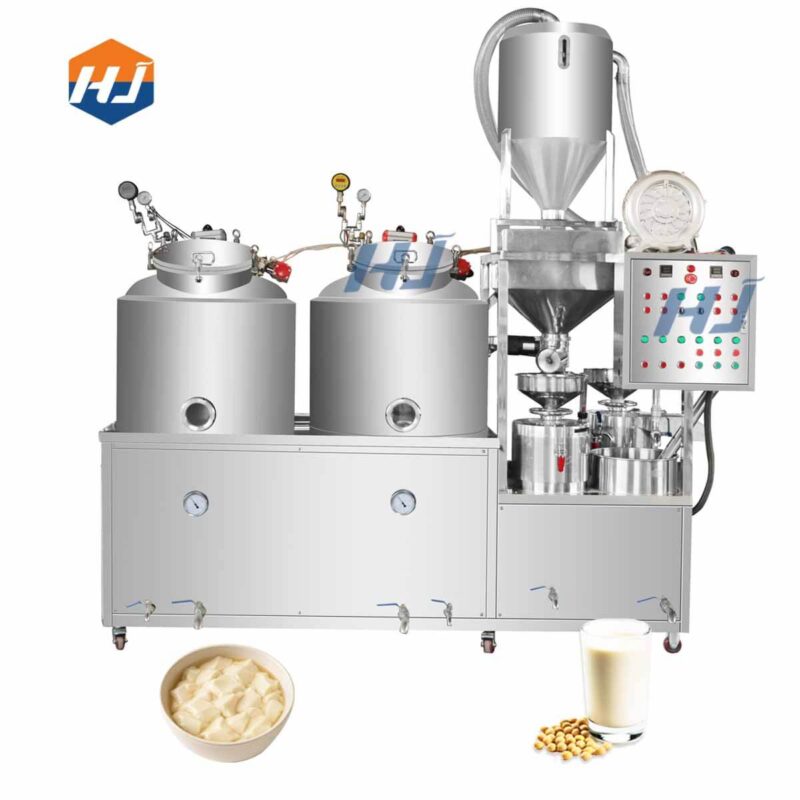

The Importance of Using a Fully Automatic Soybean Soaking and Washing System

An automatic soybean soaking and washing machine can vacuum-suck soybeans, add water quantitatively, repeatedly wash and soak them for a set time. It uses compressed air injected into the water to agitate the soybeans, ensuring thorough soaking and washing, and allowing damaged soybeans and other impurities to float on the surface. The soaked soybeans and water flow down the trough to a vibrating filter screen, which removes stones, sand, and impurities. The properly soaked and clean soybeans will not affect the taste and quality of soy milk and tofu.

Usually, to meet daily production needs, most workers need to soak and wash soybeans in the early morning. After soaking, manual filtering is required, which is labor-intensive and time-consuming. An automatic soybean soaking and washing machine can set the start time for soaking, add water quantitatively, inject compressed air at regular intervals to agitate the soybeans, and automatically filter out the clean soybeans.

Generally, in spring and autumn, soaking is done at 10-12℃ for 12-15 hours; in summer, at 28-33℃ for 5-7 hours; and in winter, for 15-22 hours. In summer, soak the beans until they are about 80% cooked, with a slightly concave shape in the center of the bean and a darker color in the middle. In winter, they can be soaked until about 90% cooked, with the bean becoming milky white and the center light yellow.