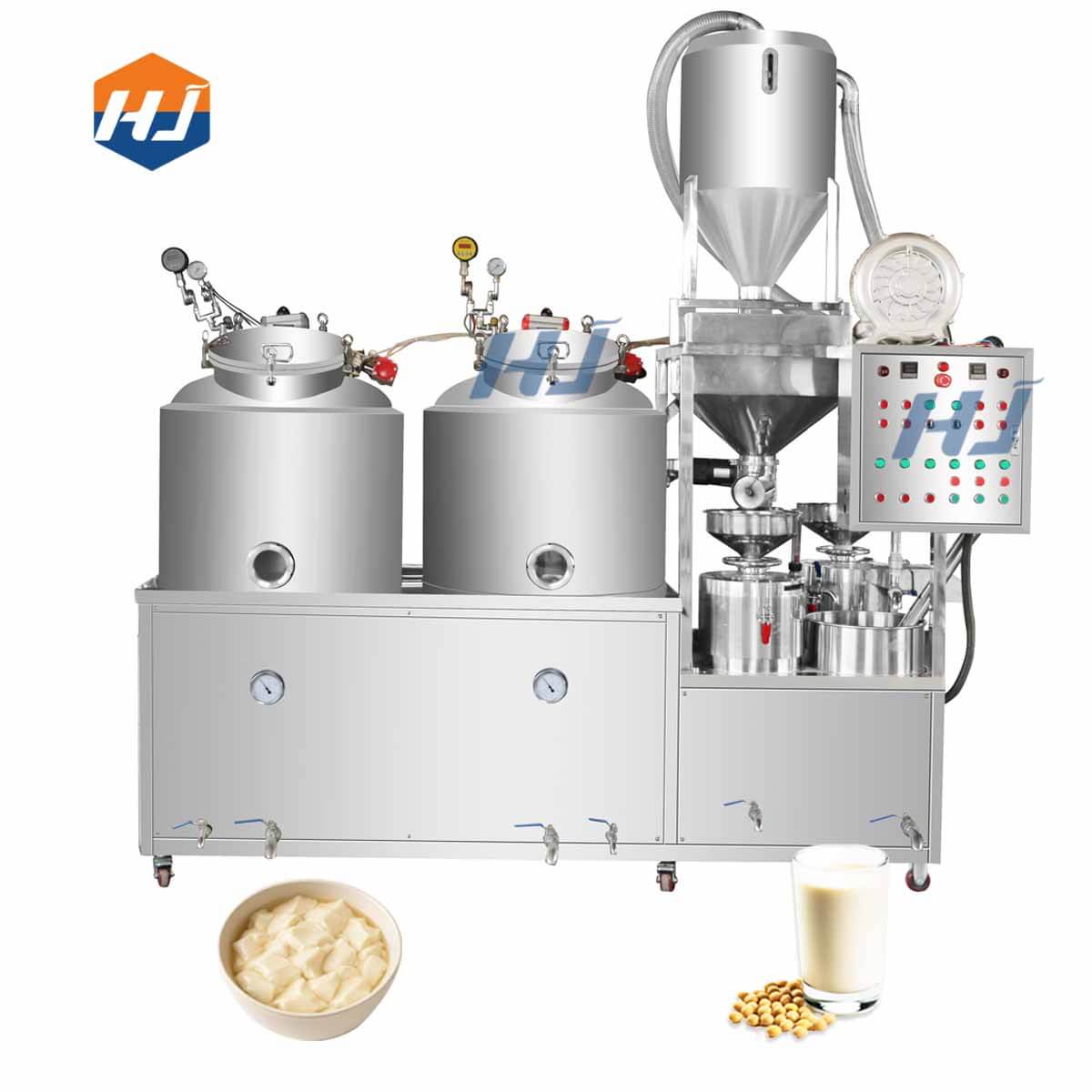

This fully automatic soymilk processing system integrates vacuum feeding, precision metering, dual-stage wet grinding circulation, and sealed micro-pressure steam cooking technology to achieve true continuous, efficient, and high-yield production.

The machine automatically lifts soybeans into the upper storage hopper using a vacuum suction system, and accurately delivers a fixed amount of beans into the grinder through the automatic dosing unit, eliminating the need for manual refilling and significantly reducing labor input while improving production stability and efficiency.

The first grinder performs the primary wet grinding and automatically separates soymilk and okara at the same time、 The discharged okara drops into a mixing tank, where water is added for thorough blending and stirring、 The slurry is then pumped into the second grinder for secondary fine grinding circulation, extracting more nutrients and residual soymilk to greatly increase the final soymilk yield.

The ground raw soymilk flows into the raw soymilk tank, and is then pumped into two sealed micro-pressure steam cooking tanks、 The sealed micro-pressure design enables faster boiling and full cooking, while using steam more efficiently to reduce overall steam consumption and energy cost.

Thanks to the optimized heat utilization, the micro-pressure cooking tanks cook soymilk more rapidly while saving steam usage without compromising quality, offering lower energy consumption and higher production output.

After reaching the required heating and cooking standard, the fully cooked soymilk is discharged smoothly from the output pipe, delivering a rich soy aroma and pure, smooth taste、 This system is ideal for downstream production of tofu, dried tofu, yuba, bean curd sheets, and other soy-based products, offering a reliable, high-efficiency solution for modern tofu plants and central kitchens.