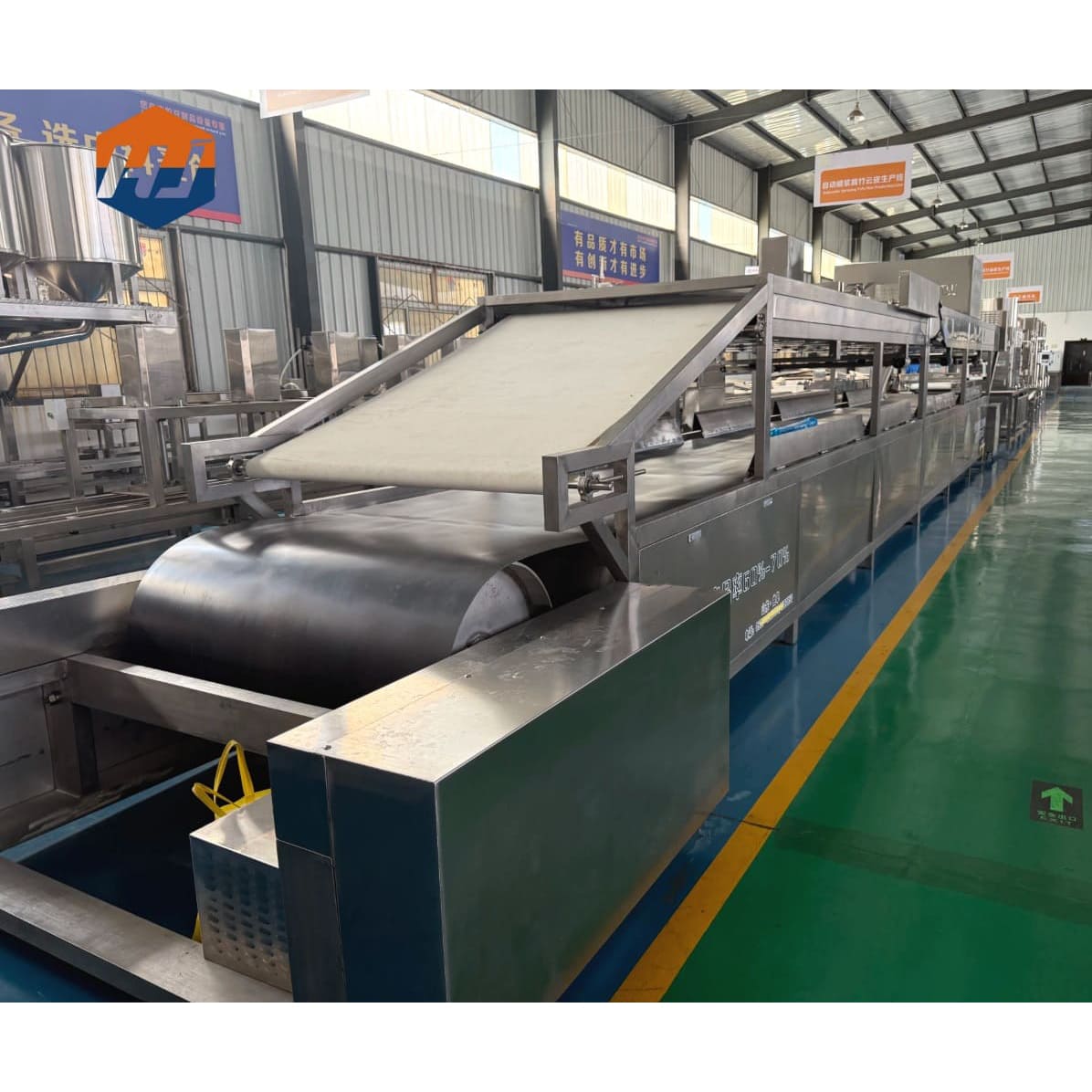

This spray-type tofu skin machine utilizes a multi-nozzle hot soymilk spraying process, delivering cooked soymilk evenly onto a continuous belt through a high-density nozzle array. The soymilk naturally solidifies on the steel belt into thin sheets, and the machine automatically peels the formed skin, enabling hands-free, continuous separation.

The nozzle system then repeatedly sprays soymilk onto a mesh belt for secondary sheet formation, achieving a stable, fully automated, and continuous closed-loop production cycle. This parallel spraying and sheet-forming mechanism ensures high rhythm stability and consistent output.

Thanks to the optimized closed spray sheet-forming process, the entire production line operates with no residual soymilk waste or material loss, significantly improving raw material utilization. The output ratio reaches approximately 0.7 kg soybean sheet per 1 kg soybeans processed, with a feeding and processing capacity of around 60 kg soybeans per hour, meeting the efficiency requirements of mid-to-large soy food manufacturing lines.

With a continuous handling rate of ≈60 kg soybeans per hour, this machine is built to support scalable, reliable yuba and soybean sheet production, making it an ideal solution for modern tofu and todu skin factories seeking high yield, process stability, and zero-waste skin formation.