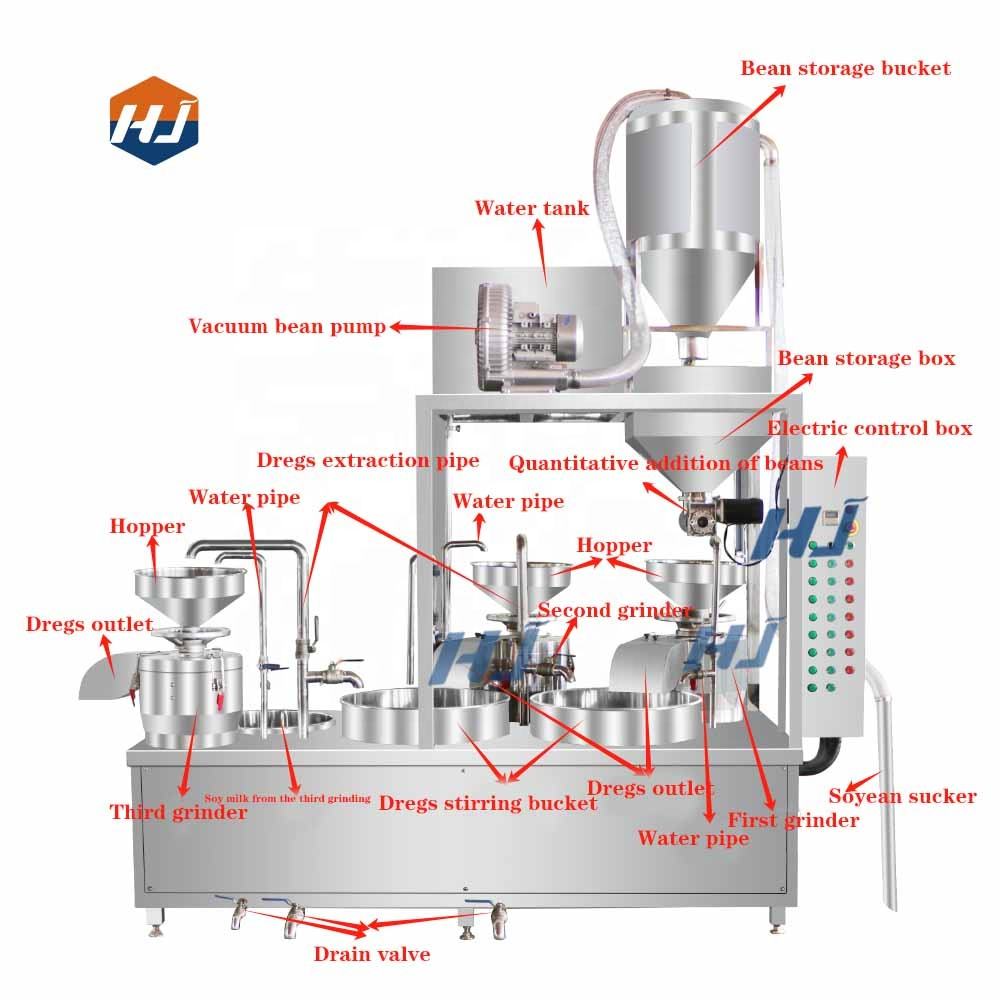

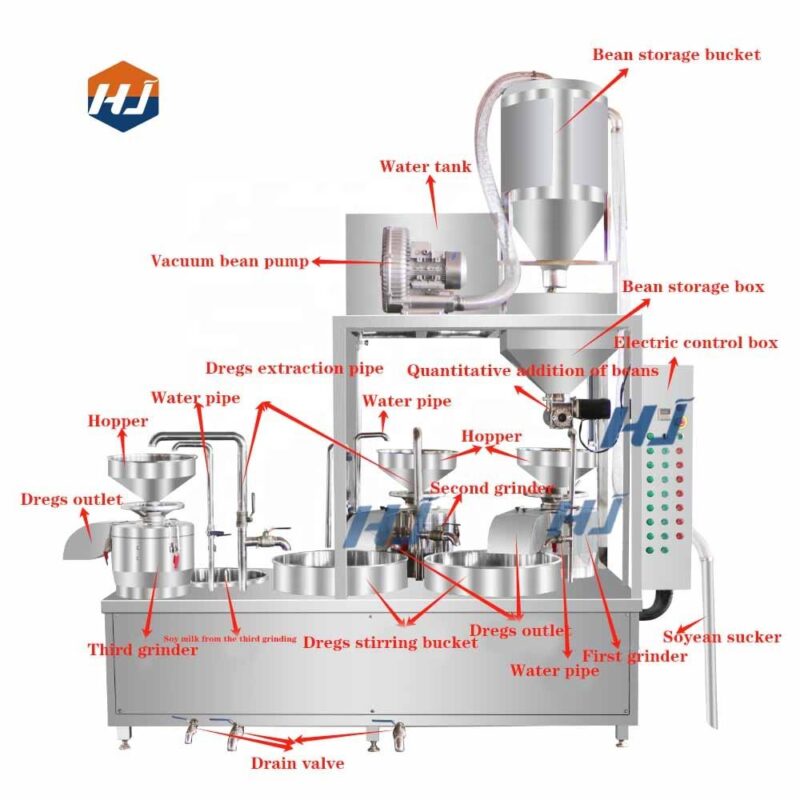

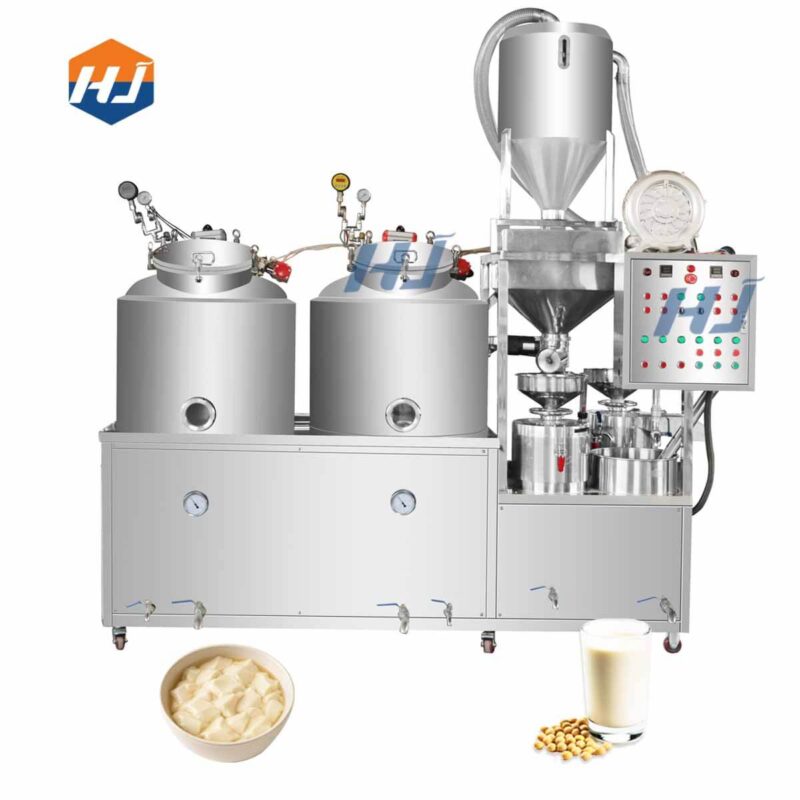

This triple-grinder system adopts an advanced automatic vacuum soybean feeding mechanism and 3-stage circulation grinding process, achieving efficient soybean processing without manual refilling. Soybeans are automatically drawn into the upper storage hopper via a vacuum suction device, and precisely metered into the first grinder, where initial grinding and automatic separation of soymilk and okara are completed simultaneously.

The separated okara naturally drops into the okara mixing tank, where water is added for thorough stirring to form a uniform slurry. The slurry is then pumped into the second grinder through a sealed pipeline for secondary grinding and re-separation, extracting more residual soymilk from the raw material to improve the total soymilk extraction rate.

After the second cycle, the discharged okara returns to the mixing tank, water is again added for full blending, and the slurry is continuously pumped to the third grinder for a third-pass grinding and extraction, ensuring the soybeans undergo three complete grinding loops to achieve a higher overall soymilk output and optimized raw material utilization.

This system enables multiple okara re-grinding cycles to extract more soymilk in total, increase soybean utilization, and raise production output, without involving changes in soymilk concentration. It is a dependable solution for modern tofu and soybean-food processing plants seeking higher yield and greater production efficiency.