उत्पाद अवलोकन

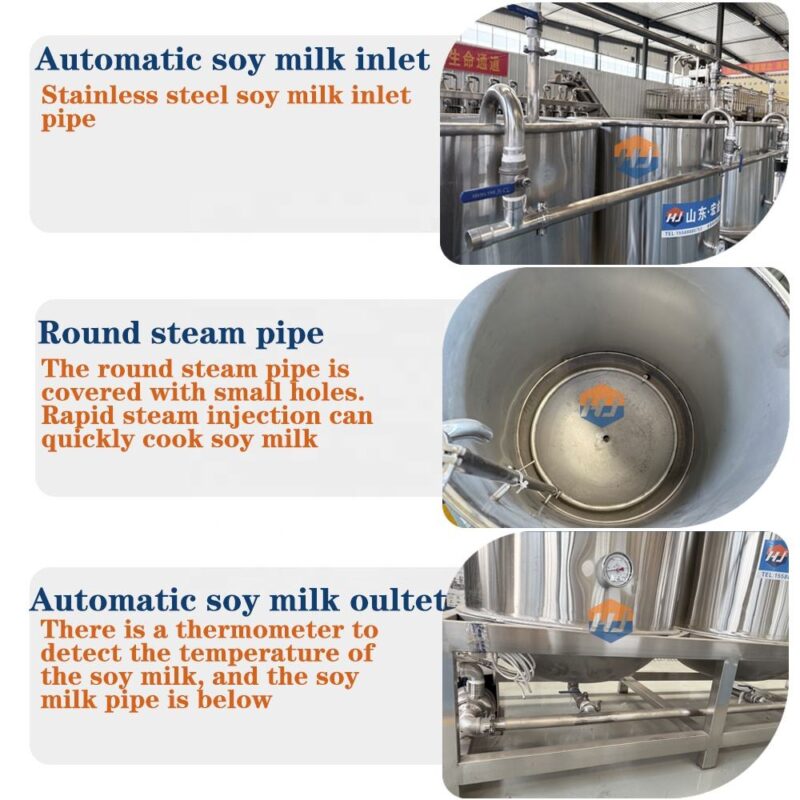

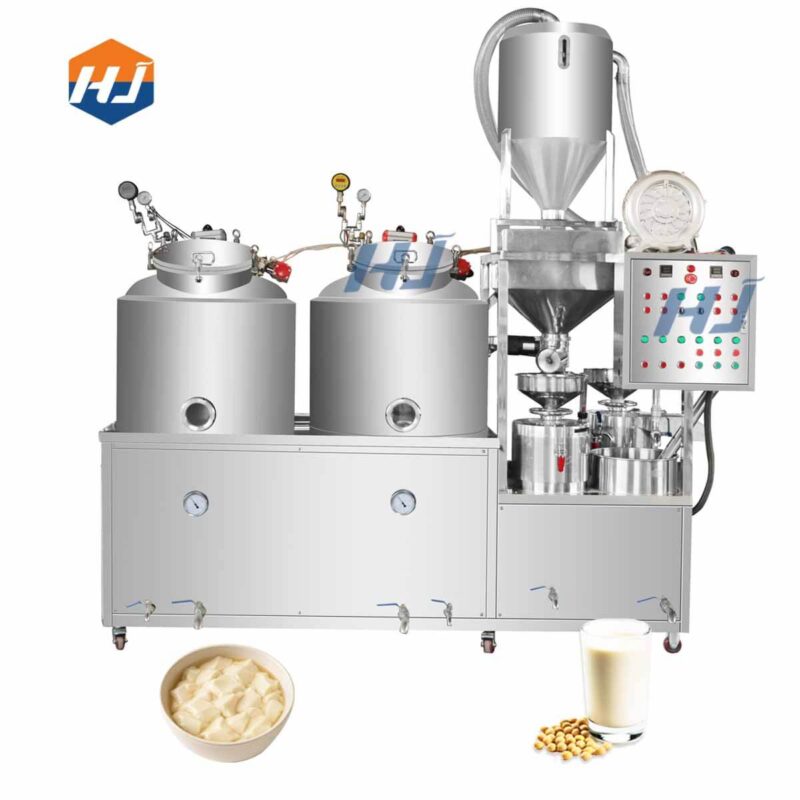

यह स्वचालित सोया मिल्क कुकिंग सिस्टम एक से अधिक परस्पर जुड़े हुए कुकिंग टैंक से मिलकर बना है, प्रत्येक में एक स्वतंत्र भाप हीटिंग पाइपलाइनभाप को टैंकों में सीधे इंजेक्ट किया जाता है, जिससे सोया मिल्क को गर्म किया जा सकता है तेजी से और समान रूप से, जिससे पूर्ण और कुशल तरीके से पकना सुनिश्चित होता है

The ओपन-टॉप टैंक डिजाइन enables operators to easily monitor the cooking process. By operating multiple cooking tanks simultaneously, the system significantly improves production efficiency and guarantees consistent soy milk quality.

यह पूरी तरह से पकी हुई सोया मिल्क ~ के उत्पादन के लिए आदर्श है टोफू, टोफू स्किन (युबा), सूखा टोफू और अन्य सोया आधारित उत्पाद.

मुख्य लाभ

समान भाप हीटिंग

प्रत्यक्ष भाप इंजेक्शन जलने और तलछट के जमाव को रोकता है, जिससे खाना पकाने के टैंक में समान गर्मी मिलती है

उच्च उत्पादन दक्षता

एक से अधिक कुकिंग टैंक लगातार काम कर सकते हैं, जो बड़े पैमाने और उच्च क्षमता वाली सोया मिल्क प्रक्रिया का समर्थन करते हैं

ऑपरेटर के अनुकूल ओपन डिजाइन

ओपन-टॉप संरचना संचालन के दौरान आसान निगरानी, हिलाने और प्रक्रिया समायोजन की अनुमति देती है

सोया मिल्क का पूर्ण पकना

अंतिम सोया उत्पादों की बनावट, चिकनाई और स्थिरता में सुधार सुनिश्चित करता है

आसान सफाई और रखरखाव

Open tanks reduce residue accumulation and simplify daily cleaning and maintenance.

लचीली कॉन्फ़िगरेशन

उत्पादन क्षमता और प्रक्रिया आवश्यकताओं के अनुसार कुकिंग टैंकों की संख्या को अनुकूलित किया जा सकता है

संचालन प्रक्रिया

1. खाना पकाने से पहले की तैयारी

सोया मिल्क पकाने से पहले, सिस्टम को पूरी तरह से साफ किया जाना चाहिए। सोया मिल्क के अवशेष अक्सर पकाने के टैंकों की आंतरिक दीवारों से चिपक जाते हैं, और अपर्याप्त सफाई अवशेषों को बाद के उत्पादन में ला सकती है, जिससे उत्पाद की गुणवत्ता प्रभावित होती है

जाँचें कि:

-

भाप का दबाव आवश्यक विनिर्देशों को पूरा करता है

-

पानी की आपूर्ति, बिजली की आपूर्ति और वाल्व ठीक से काम कर रहे हैं

-

वर्तमान उत्पादन बैच के लिए आवश्यक सोया मिल्क की सांद्रता की पुष्टि की जाती है, क्योंकि विभिन्न सोया उत्पादों के लिए विभिन्न सांद्रता की आवश्यकता होती है

2. सोया मिल्क पकाने का संचालन

-

डिस्चार्ज वाल्व खोलें और कच्चे सोया मिल्क को कुकिंग टैंक में पंप करें

-

उबलने के दौरान छलने से बचने के लिए सोया मिल्क की मात्रा~से अधिक नहीं होनी चाहिए उबलने के दौरान छलने से बचने के लिए सोया मिल्क की मात्रा तीन पांचवें हिस्से (3/5) से अधिक नहीं होनी चाहिए उबलने के दौरान छलने से बचने के लिए सोया मिल्क की मात्रा टैंक क्षमता के तीन पांचवें हिस्से (3/5) से अधिक नहीं होनी चाहिए

-

भाप का वाल्व खोलें ताकि भाप तेजी से टैंक में प्रवेश कर सके और सोया मिल्क को गर्म कर सके

3. प्रत्येक उत्पादन शिफ्ट के बाद सफाई

प्रत्येक कार्य शिफ्ट के बाद, ____ का उपयोग करके कुकिंग टैंक को पूरी तरह से साफ करें प्रत्येक कार्य शिफ्ट के बाद, क्षारीय सफाई विलयन का उपयोग करके कुकिंग टैंक को पूरी तरह से साफ करें प्रत्येक कार्य शिफ्ट के बाद, क्षारीय सफाई विलयन का उपयोग करके कुकिंग टैंक को पूरी तरह से साफ करें और आंतरिक दीवारों से अवशेष और शेष तरल को हटा दें

आसपास के कार्य क्षेत्र को साफ करें और संचालन और स्वच्छता रिकॉर्ड पूरा करें

महत्वपूर्ण संचालन नोट्स

-

सोया मिल्क में भाप इंजेक्ट करने से पहले, सुनिश्चित करें कि भाप जेनरेटर का____ सोया मिल्क में भाप इंजेक्ट करने से पहले, सुनिश्चित करें कि भाप जेनरेटर काभाप सिलेंडरठीक से काम कर रहा है voordat u stoom in de sojamelk injecteert, zorg ervoor dat de stoomcilinder van de stoomgenerator volledig is afgevoerd

-

Carefully monitor soy milk temperature, as soy milk may exhibit false boiling, which can be misleading if not properly observed

-

During daily cleaning, do not overlook the cleaning of the discharge pipeline beneath the cooking tank, where residues can easily accumulate