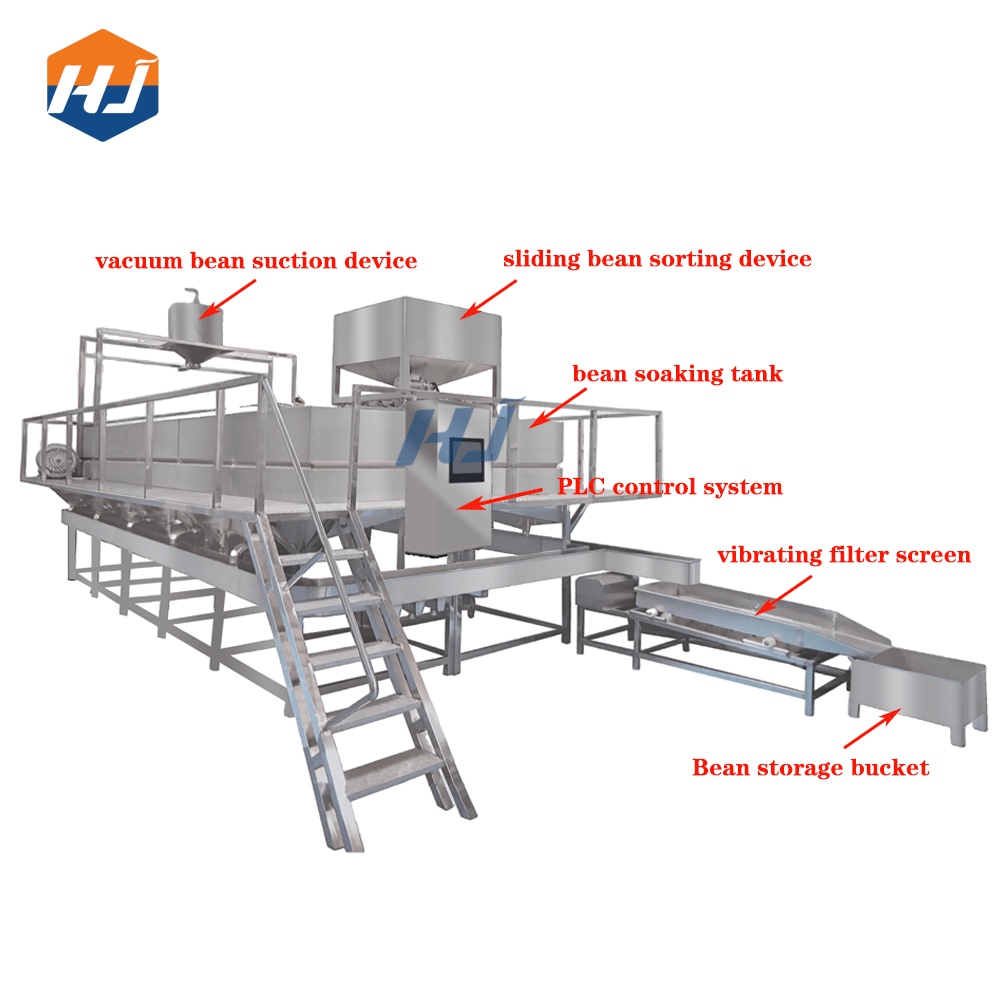

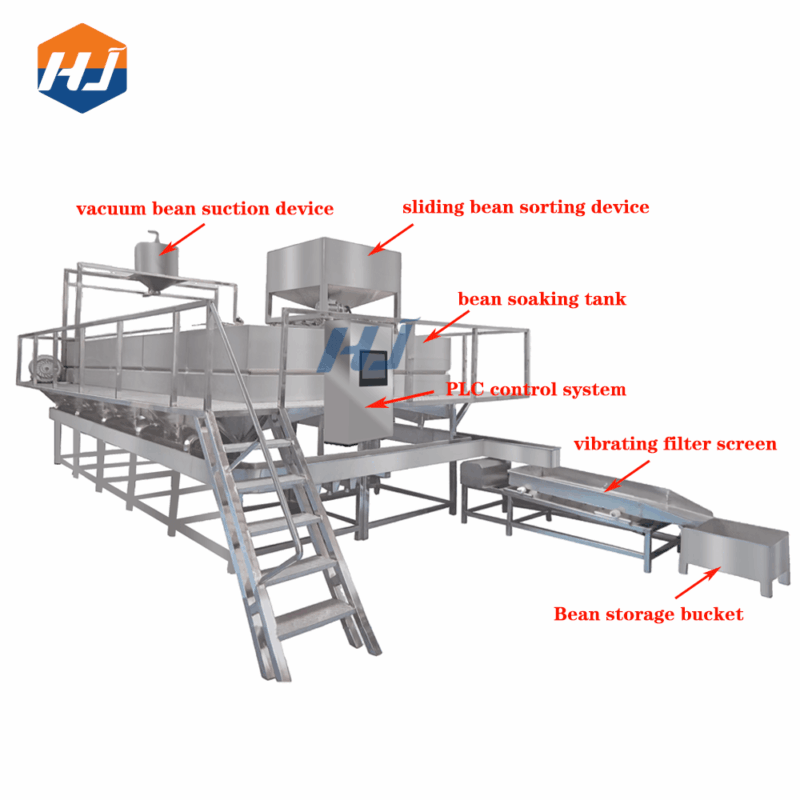

बीन धोने और भिगोने का उपकरण कारखाने की सोयाबीन उत्पाद निर्माण प्रक्रिया में पहला कदम है। पूर्ण सिस्टम में वैक्यूम बीन सक्शन डिवाइस, भंडारण हॉपर, स्लाइडिंग बीन वितरण डिवाइस, बीन वितरण ट्रैक, भिगोने का टैंक, स्टेनलेस स्टील ऑपरेटिंग प्लेटफॉर्म, स्टेनलेस स्टील सीढ़ियां, PLC स्वचालित नियंत्रण प्रणाली, स्वचालित जल भरण प्रणाली, जल स्तर का पता लगाने वाला उपकरण, वातन उपकरण, ट्रोफ फिल्टरिंग डिवाइस और कंपन फिल्टर स्क्रीन शामिल हैं। उपकरण में धोने, भिगोने, निकासी और फ़िल्टरिंग के कार्य हैं। विशेष भागों को छोड़कर पूरी मशीन स्टेनलेस स्टील से बनी है।

(1) स्वचालित खिलाना – सोयाबीन चूसने के लिए सटीक वैक्यूम नियंत्रण, मैन्युअल हैंडलिंग को समाप्त करता है।(2) प्रोग्राम करने योग्य भिगोना – इष्टतम परिणामों के लिए भिगोने का समय समायोज्य।(3) स्वचालित सफाई – कुशल सफाई और पानी बचाने के लिए बुद्धिमान जल वितरण और कुल्ला।(4) ड्रेनेज और परिवहन – साफ किए गए सोयाबीन स्वचालित रूप से अगले उत्पादन चरण में निर्वहित होते हैं।

इसका अर्थ है सोयाबीन को पूरी तरह से पानी अवशोषित करने देना। सोयाबीन की प्रोटीन झिल्ली द्वारा पानी अवशोषित और सूजन आने के बाद, इसकी बनावट कठोर से भंगुर, फिर नरम हो जाती है। भंगुर अवस्था में, पीसने के दौरान प्रोटीन झिल्ली आसानी से टूट जाती है। प्रोटीन झिल्ली के टूटने के बाद, प्रोटीन पानी में फैल सकता है, प्रोटीन कोलॉइड बनाता है, जो सोया मिल्क है।

सोयाबीन भिगोने की डिग्री:

(1) सोयाबीन का स्वरूप

बेतरतीब थोड़ी मात्रा में भिगोई हुई सोयाबीन लेकर पानी के कंटेनर में डालें। देखें कि सोयाबीन का पानी अवशोषण उपयुक्त है या नहीं। उपयुक्त पानी अवशोषित करने वाली सोयाबीन की बाहरी विशेषताएं निम्नलिखित हैं:

1)सोयाबीन के दाने पूरी तरह से फूले हुए होने चाहिए, और फूलने की मात्रा पूरे में समान होनी चाहिए;

2)सोयाबीन के दाने पूरी तरह से फूले हुए होने चाहिए, और फूलने की मात्रा पूरे में समान होनी चाहिए;

सोयाबीन की खाल लगभग पारदर्शी होनी चाहिए और सोयाबीन के दानों से अलग नहीं होनी चाहिए।

जब एक मुट्ठी सोयाबीन को पकड़कर कसकर निचोड़ा जाता है, तो एक स्पष्ट "कठोर", "दृढ़" और प्रतिक्षेपित सनसनाहोनी चाहिए, और एक "क्रंचिंग" ध्वनि उत्पन्न होनी चाहिए। पकड़ छोड़ने के बाद, सोयाबीन की खाल के गिरने की संख्या 1/10 से कम होनी चाहिए, और टूटने की दर 1/15 से अधिक नहीं होनी चाहिए।

(2)सोयाबीन की आंतरिक विशेषताएं

अवलोकन के लिए कुछ भिगोई हुई सोयाबीनों को यादृच्छिक रूप से चुनें। उपयुक्त जल अवशोषण वाली सोयाबीनों की आंतरिक विशेषताएं निम्नलिखित हैं:

सोयाबीन का केंद्र आसपास के क्षेत्र की तुलना में लगभग सपाट होना चाहिए, जिसमें थोड़ा सा अवतल हो।

यदि आप सोयाबीन के केंद्र में एक संकीर्ण रेखा देख सकते हैं जो आसपास के क्षेत्र से थोड़ी गहरी है, तो इसका मतलब है कि सोयाबीन ने लगभग 90% पानी अवशोषित कर लिया है, जो सोया मिल्क बनाने के लिए आवश्यक भिगोने का स्तर है।

जब आप हाथ से सोयाबीन तोड़ते हैं, तो यह बहुत कुरकुरी आवाज निकालता है, और टूटा हुआ सिरा सपाट और किनारे साफ-सुथरे होते हैं।

हाथों से रगड़कर सोयाबीन के बीजों का परीक्षण करते समय, उचित रूप से भिगोई हुई सोयाबीन की बाहरी खाल को हटाना आसान होता है। हालांकि, पूरी सोयाबीन को दो हिस्सों में अलग करना बाहरी खाल को हटाने की तुलना में काफी कठिन है, दोनों हिस्सों को अलग करने के लिए जानबूझकर बल की आवश्यकता होती है, साथ ही हल्की आवाज भी आती है।

(3)सोयाबीन की गंध

भिगोने के बाद सोयाबीन में तेज़ “कच्ची” गंध होनी चाहिए। यह “कच्ची” गंध सोयाबीन की प्राकृतिक गंध के साथ हरे पौधों की विशेषता वाली हल्की मिट्टी और हरे रंग की गंध के मिश्रण से उत्पन्न होने वाली एक अनोखी खुशबू है। कोई खट्टी या सड़ी हुई गंध नहीं होनी चाहिए। यह भिगोए हुए सोयाबीन की गुणवत्ता नियंत्रण में एक महत्वपूर्ण बिंदु है।

(4) सोयाबीन की नमी मात्रा

भिगोए हुए सोयाबीन की आवश्यक नमी मात्रा सोयाबीन की किस्म, उत्पत्ति, वसा सामग्री, विकास चक्र और मिट्टी की स्थितियों के आधार पर थोड़ी भिन्न होती है, लेकिन आमतौर पर लगभग 59% होनी चाहिए। भिगोए हुए सोयाबीन का प्रसार गुणांक 1.8 से 2.2 गुना के बीच होना चाहिए।

(5) भिगोने वाले पानी का pH मान

भिगोने वाले पानी का pH मान ≥6.5 होना चाहिए और इससे कम नहीं होना चाहिए। पानी का रंग हल्का पीला या फीका पीला होना चाहिए।

यदि निम्नलिखित स्थितियां होती हैं, तो यह इंगित करता है कि सोयाबीन पर्याप्त रूप से भिगोए नहीं गए हैं: सोयाबीन की बाहरी खाल में अभी भी स्पष्ट झुर्रियां हैं, और सोयाबीन की सतह पर्याप्त चमकदार, गोल या नम नहीं है। सोयाबीन के दाने के आंतरिक भाग में एक तिहाई से अधिक का गहरा डिप होना चाहिए, भिगोने से पहले के समान रंग का, आसपास के भिगोए हुए सोयाबीन के फीके पीले रंग के साथ स्पष्ट सीमाओं के साथ तीव्र विपरीत; सोयाबीन आसानी से नहीं टूटने चाहिए, केवल कुछ झुकाव और विकृति दिखानी चाहिए; भिगोने वाला पानी स्पष्ट होना चाहिए, केवल थोड़ा पीला-भूरा।

यदि निम्नलिखित स्थितियां देखी जाती हैं, तो यह इंगित करता है कि सोयाबीन अतिरंजित भिगोए गए हैं: भिगोने वाला पानी लगभग पीला-भूरा है, उल्लेखनीय खट्टी गंध है, और कुछ झाग दिखाई दे सकते हैं। जब मुट्ठी भर सोयाबीन को कसकर निचोड़ा जाता है, तो यह मुलायम, नरम, चिकना और चिपचिपा महसूस होता है, लोच की कमी होती है, सोयाबीन के आपस में रगड़ने की आवाज नहीं होती है, और स्पर्श में "रेतीला" नहीं होता है; छोड़ने पर अधिकांश सोयाबीन की खाल आसानी से उतर जाती है, और सोयाबीन के दाने इसके साथ ही अलग हो जाते हैं। अलग हुए दाने चपटे और ढीले होते हैं, उनका रंग फीका पीला होता है, मुख्य रूप से फीका सफेद; सोयाबीन दाने के किनारे पानी में भिगोने के समान सफेद दिखाई देते हैं, और वे बिना कुरकुरे आवाज के आसानी से टूट जाते हैं।

संपूर्ण स्वचालित सोयाबीन भिगोने और धोने की प्रणाली के उपयोग का महत्व

स्वचालित सोयाबीन भिगोने और धोने की मशीन वैक्यूम द्वारा सोयाबीन को चूस सकती है, मात्रा में पानी जोड़ सकती है, बार-बार धो सकती है और निर्धारित समय के लिए भिगो सकती है। यह पानी में संपीड़ित हवा का उपयोग करके सोयाबीन को हिलाती है, जिससे पूरी तरह से भिगोने और धोने की सुनिश्चित होती है और क्षतिग्रस्त सोयाबीन और अन्य अशुद्धियां सतह पर तैर जाती हैं। भिगोए हुए सोयाबीन और पानी नली से नीचे कंपन फिल्टर स्क्रीन पर प्रवाहित होते हैं, जो पत्थर, रेत और अशुद्धियों को हटाता है। उचित रूप से भिगोए और साफ सोयाबीन सोया दूध और टोफू के स्वाद और गुणवत्ता को प्रभावित नहीं करते हैं।

आमतौर पर, दैनिक उत्पादन आवश्यकताओं को पूरा करने के लिए अधिकांश श्रमिकों को सुबह जल्दी सोयाबीन को भिगोने और धोने की जरूरत होती है। भिगोने के बाद मैन्युअल फिल्टरिंग की आवश्यकता होती है, जो श्रमसाध्य और समय लेने वाली है। स्वचालित सोयाबीन भिगोने और धोने की मशीन भिगोने का प्रारंभ समय निर्धारित कर सकती है, मात्रा में पानी जोड़ सकती है, नियमित अंतराल पर सोयाबीन को हिलाने के लिए संपीड़ित हवा का इंजेक्शन कर सकती है और स्वचालित रूप से साफ सोयाबीन को फ़िल्टर कर सकती है।

Generally, in spring and autumn, soaking is done at 10-12℃ for 12-15 hours; in summer, at 28-33℃ for 5-7 hours; and in winter, for 15-22 hours. In summer, soak the beans until they are about 80% cooked, with a slightly concave shape in the center of the bean and a darker color in the middle. In winter, they can be soaked until about 90% cooked, with the bean becoming milky white and the center light yellow.