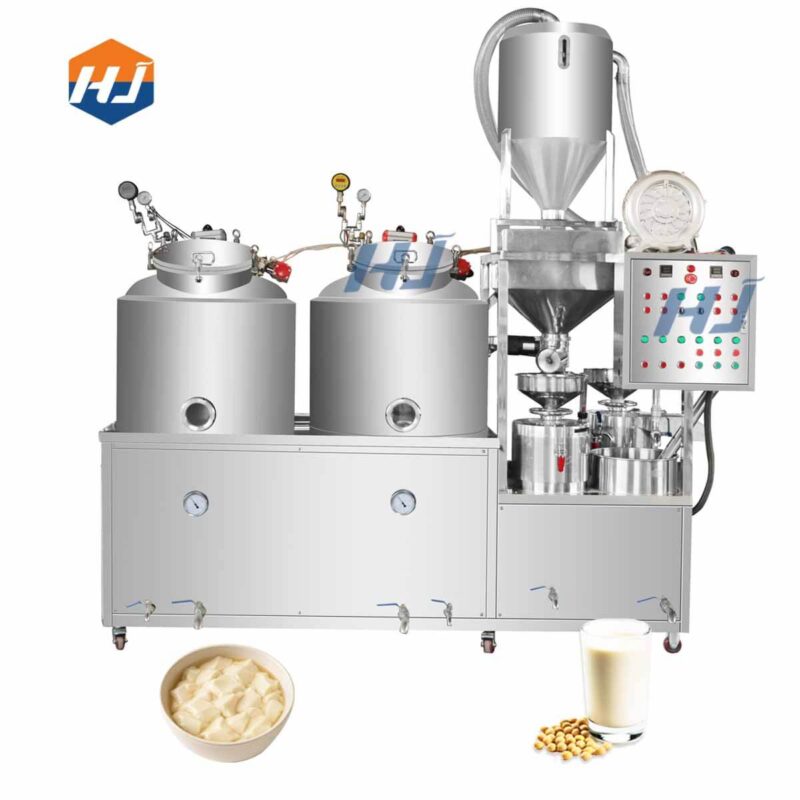

This fully automatic quadruple soybean grinding system integrates a vacuum feeding mechanism and 4-stage circulation grinding process, delivering continuous, stable, and high-efficiency soymilk extraction.

Soybeans are automatically drawn into the upper storage hopper using a vacuum suction device, then accurately metered and fed into the first grinder, which processes whole soybeans into a smooth paste. The first grinder adopts a low-speed, preventing overheating during grinding, and maintaining a gentle processing temperature to ensure efficient downstream protein utilization without compromising raw material integrity.

The soybean paste is then transferred to the second grinder separator, where automatic solid-liquid separation is performed to extract the first batch of raw soymilk. The discharged okara falls into the okara mixing tank, where water is added for thorough stirring to form a uniform recyclable slurry. This slurry is pumped through a sealed pipeline into the third grinder for tertiary grinding and separation, extracting additional usable soymilk from the raw material.

After the third cycle, the okara returns to the mixing tank again for re-hydration and stirring, then is continuously pumped into the fourth grinder for a final extraction round.

Thanks to the optimized 4-stage closed-loop re-grinding and separation process, soybeans undergo multiple automated grinding and separation cycles, achieving a higher total soymilk output, greater raw material utilization, and increased production capacity—without implying any change in soymilk concentration.

This system eliminates repeated manual soybean loading, improves overall production efficiency, and is a reliable, high-yield solution for modern tofu plants and industrial soymilk processing lines.