GDL tofu

GDL tofu, also known as silken tofu or soft tofu, is made using GDL as the coagulant. It is known for its silky-smooth texture, uniform structure, and pudding-like softness. Unlike traditional salt-coagulated tofu, GDL tofu has a cleaner taste, whiter appearance, and no holes, thanks to its gentle and uniform coagulation process.

Benefits of GDL tofu:

Exceptionally smooth and silky texture: Soft and delicate, ideal for children, seniors, and consumers who prefer tender foods.

Highly nutritious: Rich in plant protein, calcium, and minerals while being low in fat.

Mild and clean flavor: GDL provides gentle coagulation without bitterness or off-flavors.

Wide culinary applications: Suitable for packaged tofu products, hot pot, salads, soups, steamed dishes, desserts, and more.

Lactone(soft) tofu product line(GDL tofu)

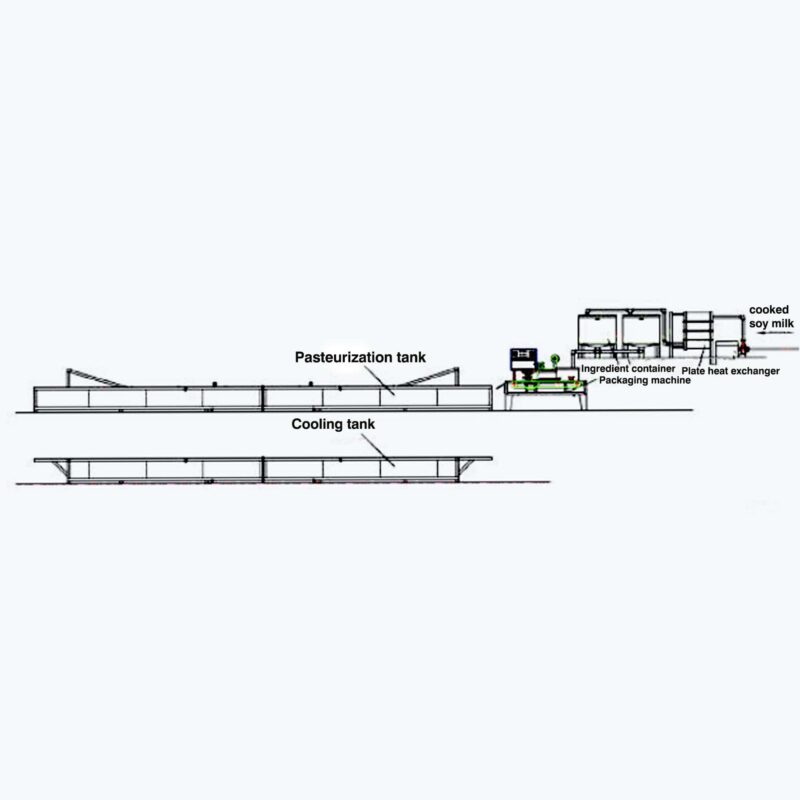

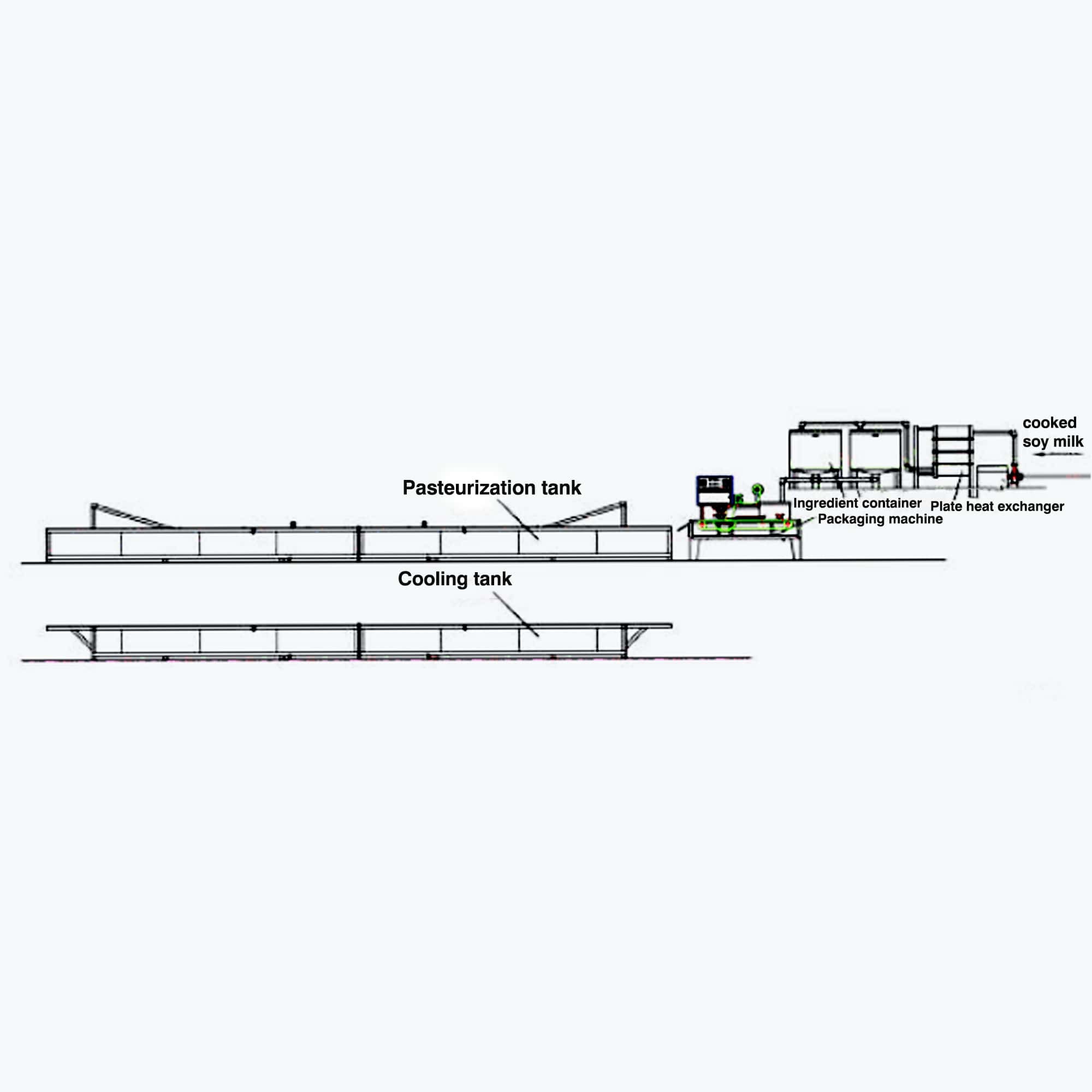

Process Flow: Soaking soybeans – Grinding – Boiling – Filtration – Plate heat exchanger – Ingredient mixing – Filling – Pasteurization and setting – Cooling – Inspection and warehousing.

The production of tofu, dried tofu, silken tofu, tofu skin, and other soy products all require soaking the soybeans, grinding them into soy milk, boiling the soy milk, and filtering it in the initial stages. Therefore, they can all use the same equipment in the early stages, but different equipment is used during the shaping stage.

For silken tofu, during the shaping stage, the cooked soy milk is passed through a plate heat exchanger to cool it down. The cooled soy milk then has glucono delta-lactone added in a mixing tank, and is then filled into containers by a packaging machine, followed by pasteurization and cooling in a pasteurization tank and cooling tank, respectively.

Small sliken tofu filling machine

The cooked soy milk is pumped to a storage tank and then rapidly cooled by a plate heat exchanger. The cooled soy milk is mixed with glucono-delta-lactone (GDL) in the ingredient mixing tank of the tofu machine. TThe machine fills the mixed glucono delta-lactone soy milk into food-grade plastic boxes, seals them, trims the edges, and codes them. Then, it is heated in a heating tank while being pasteurized, coagulated, and finally cooled in a cold water tank.

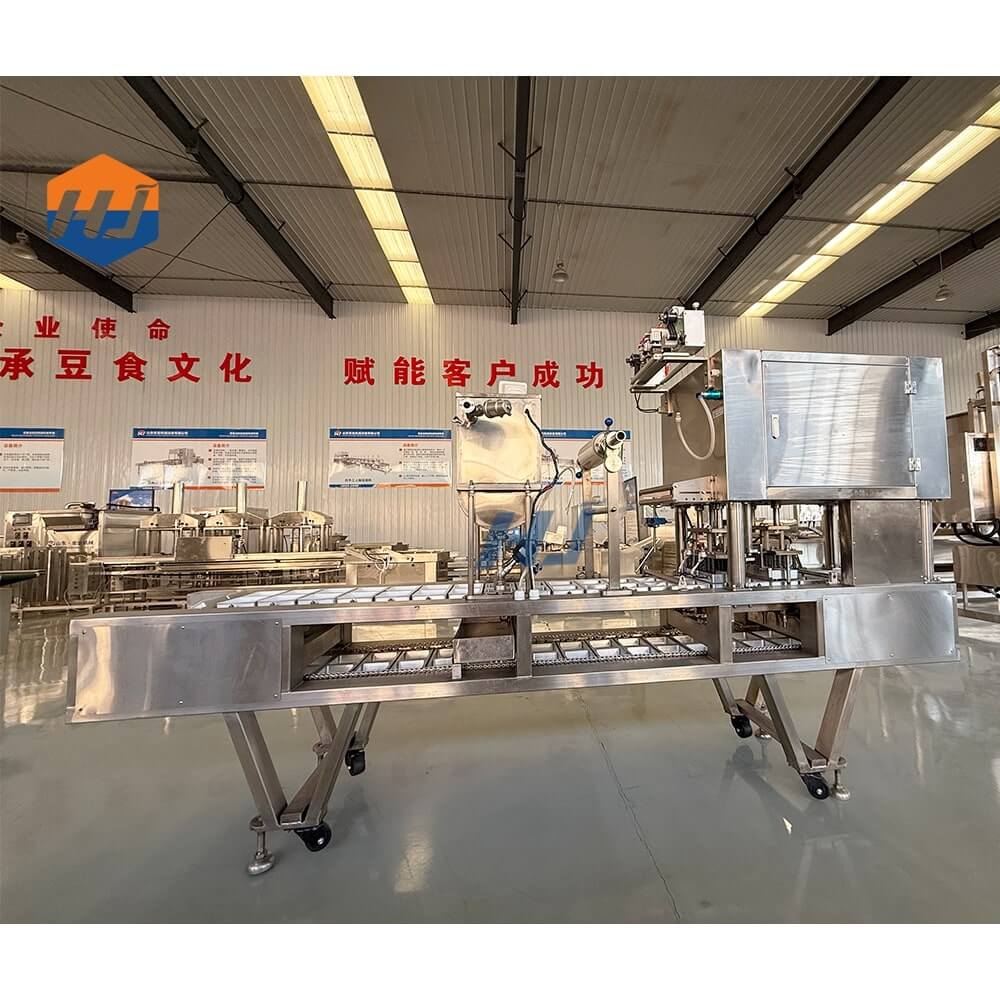

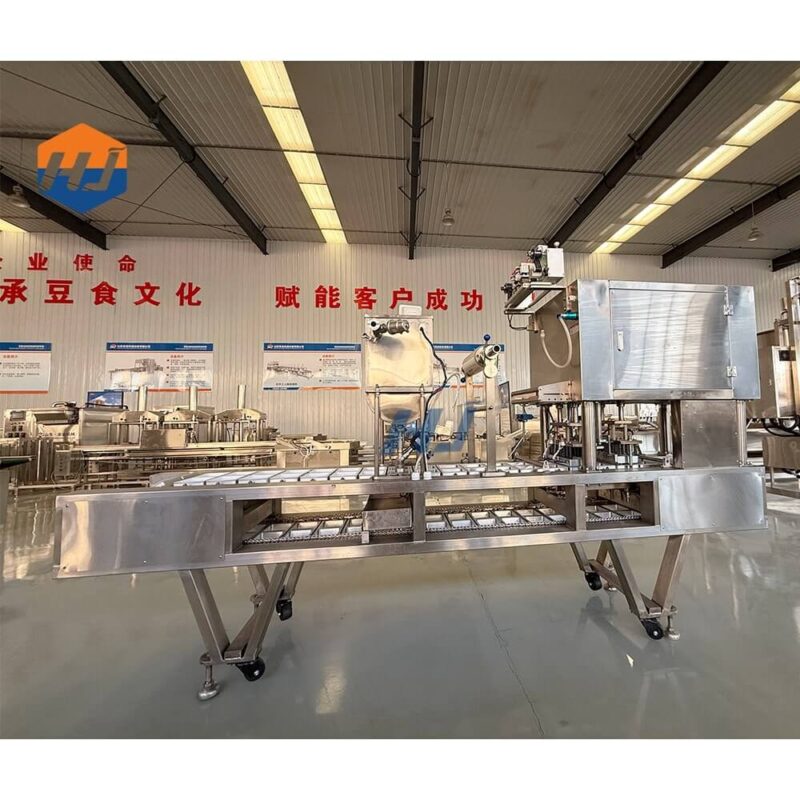

Large sliken tofu filling machine

The cooked soy milk is pumped to a storage tank and then rapidly cooled by a plate heat exchanger. The cooled soy milk is mixed with glucono-delta-lactone (GDL) in the ingredient mixing tank of the tofu machine. TThe machine fills the mixed glucono delta-lactone soy milk into food-grade plastic boxes, seals them, trims the edges, and codes them. Then, it is heated in a heating tank while being pasteurized, coagulated, and finally cooled in a cold water tank.

Pasteurization tank

The pasteurization tank is made of food-grade 304 stainless steel and is used for long-term pasteurization of tofu, silken tofu, and other similar products. The equipment uses hot water in the heating tank to maintain the product at a constant sterilization temperature for a specific time, effectively killing harmful bacteria, extending shelf life, and preserving the product’s taste and nutritional value.

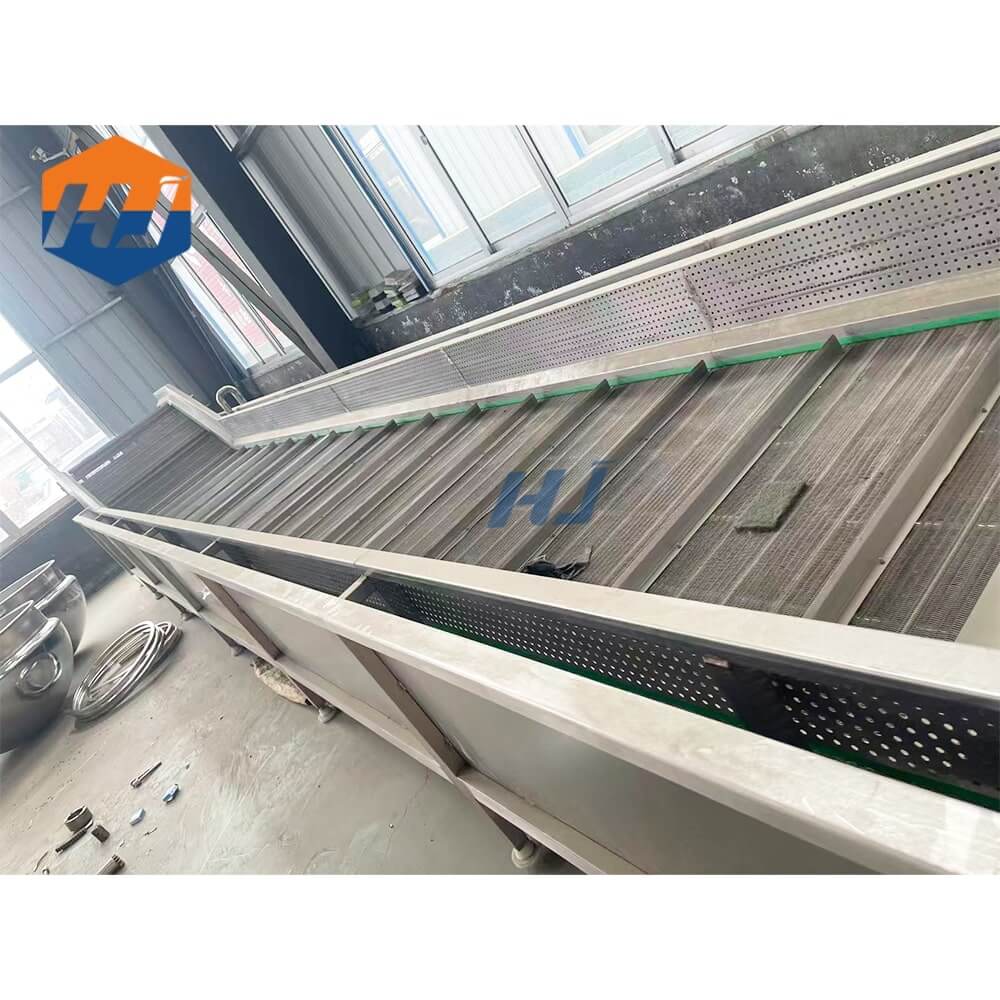

Cooling tank

The cooling tank is mainly used for rapid cooling and stabilization of silken tofu after thermal coagulation. After coagulation, the inside of the silken tofu remains at a relatively high temperature. If it is not cooled promptly, it can easily become overcooked, release too much water, and develop a tough texture. The cold water circulation system in the cooling tank quickly lowers the temperature of the silken tofu, maintaining its delicate and smooth texture.

Precautions for producing silken tofu

(1)Preparation of GDL Solution

Because GDL gradually hydrolyzes into gluconic acid in water, improper preparation may cause premature coagulation when mixed with soy milk. Therefore, the GDL solution should be prepared fresh and diluted with 2–2.5 times cold water to delay hydrolysis and ensure uniform mixing.

(2)Control of Soy Milk Solid Content

The solid content of soy milk for GDL tofu is generally controlled between 9.5% and 12.5%, depending on soybean variety and product requirements. Low concentration results in weak structure, while excessive concentration leads to rough texture and excessive hardness.

(3)Degassing of Soy Milk

Micro air bubbles in soy milk tend to expand during coagulation, forming voids inside the tofu. Degassing removes entrapped air and volatile off-flavors, resulting in a smoother texture, finer structure, and improved sensory quality.

(4)Temperature Control During Mixing

GDL should be mixed with soy milk at temperatures below 30°C. Excessive temperature causes instant gelation and poor texture, while lower temperatures are acceptable but increase energy consumption during heating.

(5)Stirring Speed Control During GDL Addition

During GDL addition, soy milk should be stirred at 65–75 rpm, followed by an additional 0.5–1 minute of mixing. Insufficient stirring leads to uneven coagulation, while excessive speed introduces fine bubbles that affect product structure.

(6)Control of GDL Dosage

The dosage of GDL directly affects tofu firmness and flavor. Higher dosage improves gel strength but excessive amounts result in noticeable sourness. Dosage is typically calculated based on soy milk volume or dry soybean input.

(7)No Holding After Mixing

Once mixed, coagulation begins immediately. The mixture should be filled within 15–20 minutes, as holding will cause premature gelation and negatively affect product quality.

(8)Heating and Gelation Conditions

After filling, the product should be heated in a water bath at 80–90°C for 30–40 minutes. Lower temperatures result in weak gel strength, while excessive temperatures cause bubbling, syneresis, and rough texture.

(9)Rapid Cooling After Gelation

Rapid cooling after gelation strengthens the gel structure, improves shape retention, and significantly extends shelf life.