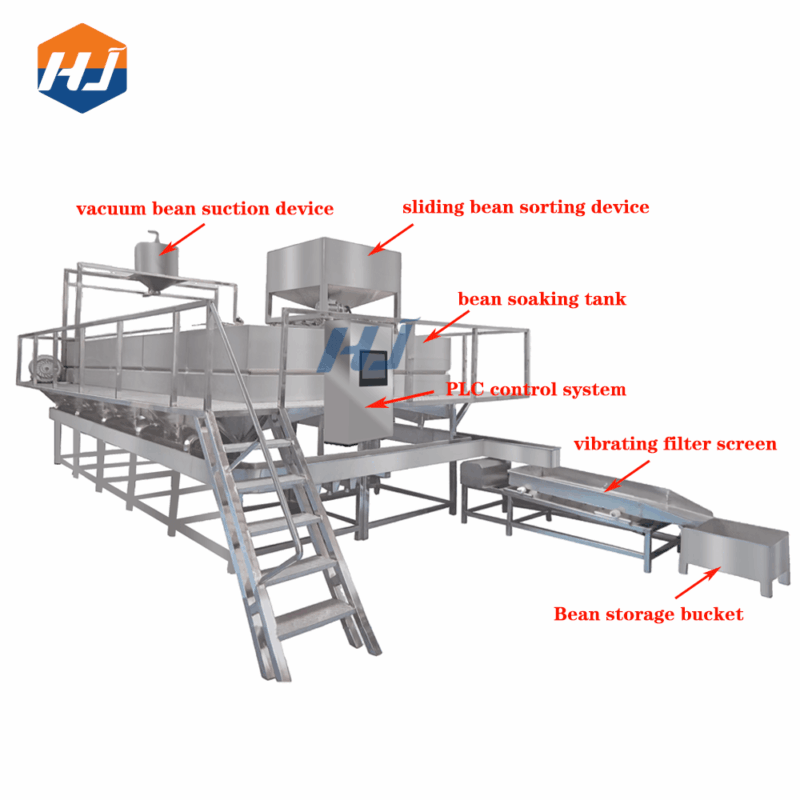

This fully automated soymilk production system is equipped with a vacuum feeding device that automatically draws soybeans into the upper storage hopper、 The beans are then precisely metered and fed into the grinder without the need for manual loading, significantly reducing labor intensity and improving operational efficiency.

The first grinder performs the initial grinding and automatically separates the soymilk from the okara、 The separated okara falls into the mixing tank, where water is added to create a uniform slurry、 This mixture is pumped to the second grinder for a refined secondary grinding, maximizing the extraction of remaining soymilk.

All extracted raw soymilk flows into the raw soymilk tank and is then pumped into two steam-heated cooking tanks、 Inside the cookers, the soymilk is efficiently heated and fully boiled、 The finished soymilk flows smoothly out through the discharge pipe, ready for downstream processes such as tofu, dried tofu, or yuba production.

The system integrates automatic vacuum feeding, dual-stage grinding, and simultaneous cooking, enabling continuous and highly efficient production、 It is an ideal solution for modern soybean product manufacturing lines seeking high yield and fully automated processing.