Soy Protein Extruder

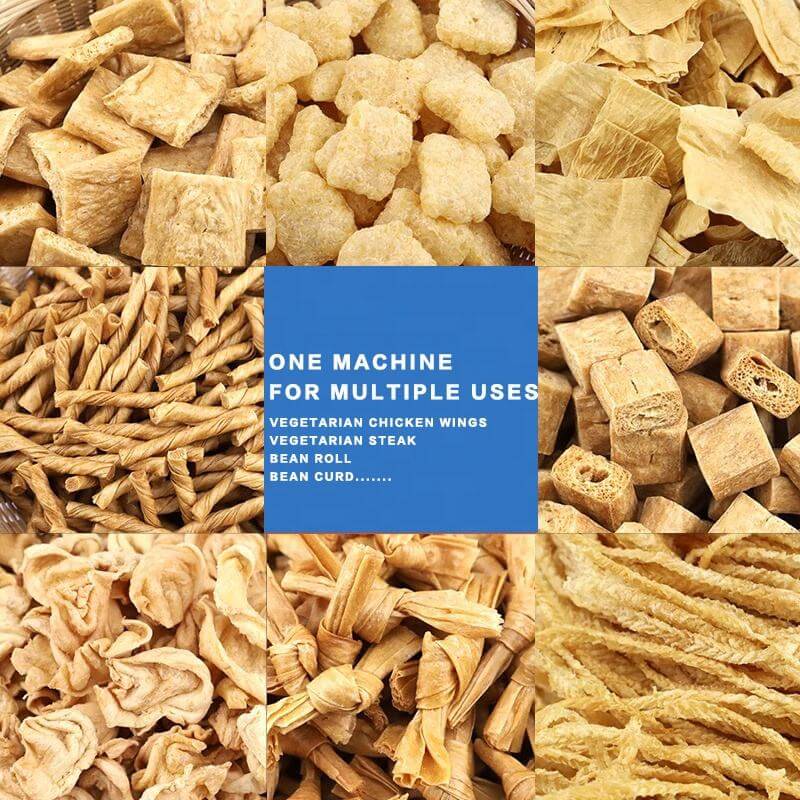

The production process begins with soybeans or soybean meal powder as raw materials. By changing the molds, more than a dozen vegetarian meat (plant protein) products with similar textures and appearances to steak, chicken wings, etc., can be produced in sheet, block, or specific shapes.

Operating procedures

- Oil press: Extracts oil from soybeans and separates soybean meal.

Suitable for: soybeans, peanuts, rapeseed, sunflower seeds, sesame seeds, etc. - Grinding machine: Grinds soybean meal cake into flour-like form.

- Mixing machine: Mix soybean meal powder with water.

- Artificial meat machine (tofu skin machine/Soy protein extruder): This machine deforms, cooks, and extrudes soybean meal powder into molds.

- Shredder: Cuts tofu skin into shreds with adjustable width.

Oil press

This soybean oil press integrates feeding, cold pressing, oil extraction, and soybean meal separation into one streamlined cycle, delivering a true “one-pass, fully automatic pressing system.” Once the seeds are loaded into the hopper, the machine drives them forward with an optimized spiral screw extrusion mechanism, applying pure physical cold-press technology at controlled low temperatures, continuously discharging oil while simultaneously ejecting soybean meal cake — no secondary pressing or manual operation required.

Suitable for cold-pressing a wide variety of oil seeds, including:

Soybeans, Peanuts, Rapeseed (Canola), Sunflower Seeds, Black Oil Sunflower, Sesame Seeds, and more.

Soybean cake crusher

Through impact crushing, when materials enter the crushing chamber, they are subjected to high-intensity and high-frequency impacts from the crushing discs, resulting in rapid crushing into powder. The powder is then discharged through the outlet under centrifugal force and airflow. This machine can crush soybean cake into powder.

Materials used: Soybeans, soybean meal, corn, wheat, rice, chili peppers, Sichuan peppercorns, coffee beans, etc.

Soybean meal flour mixer

The mixer automatically mixes water and soybean meal powder at high speed, achieving uniform mixing. It can also be used to mix flour.

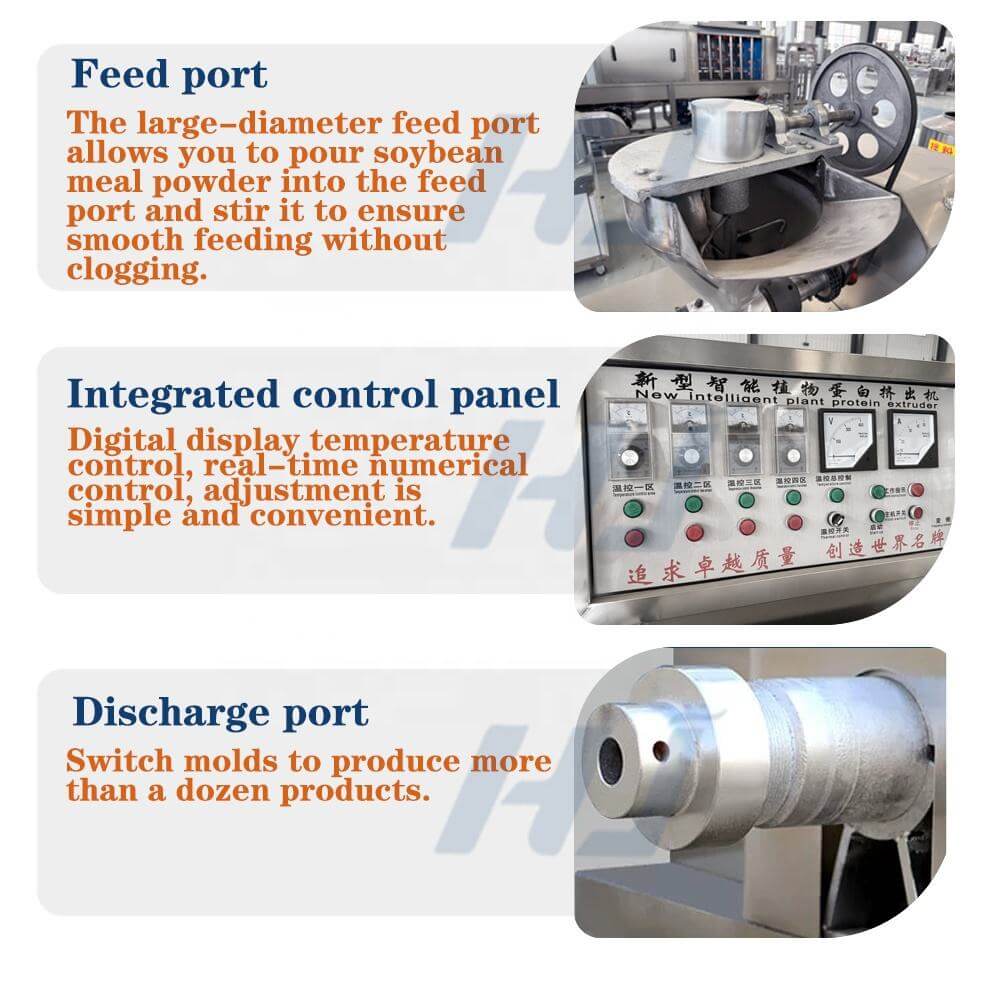

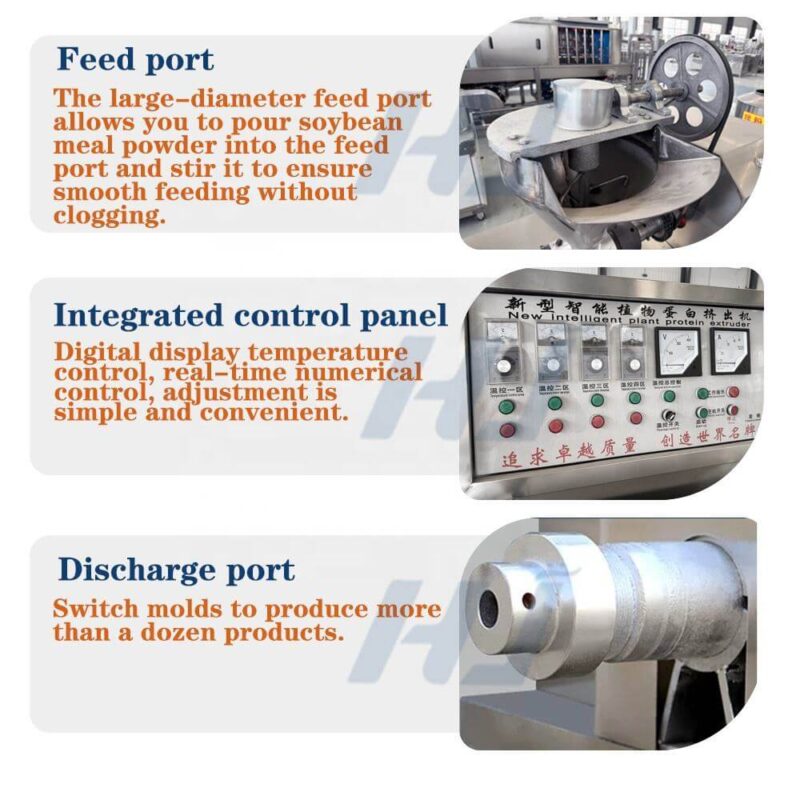

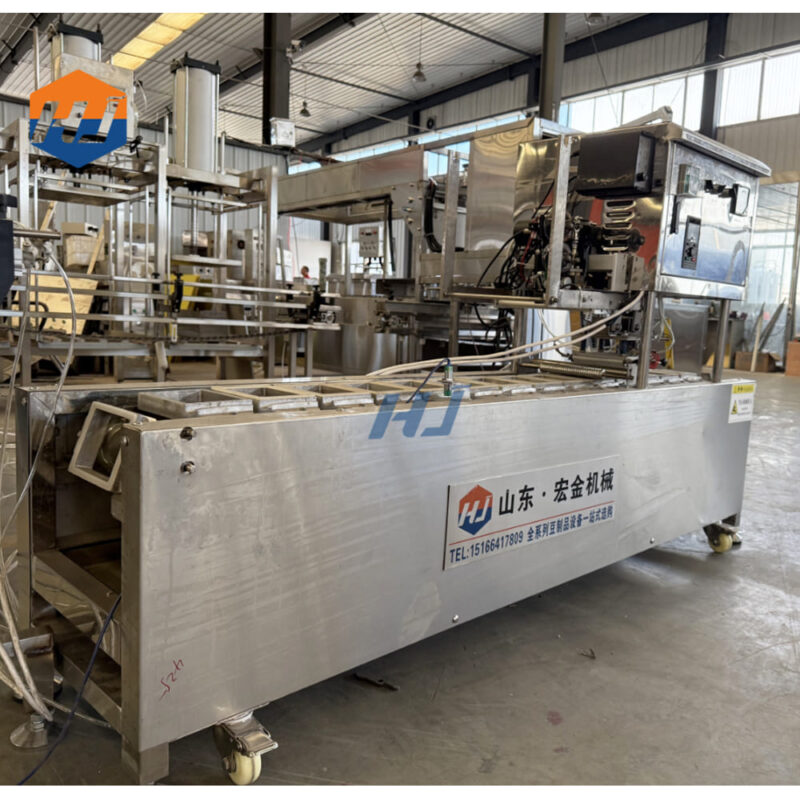

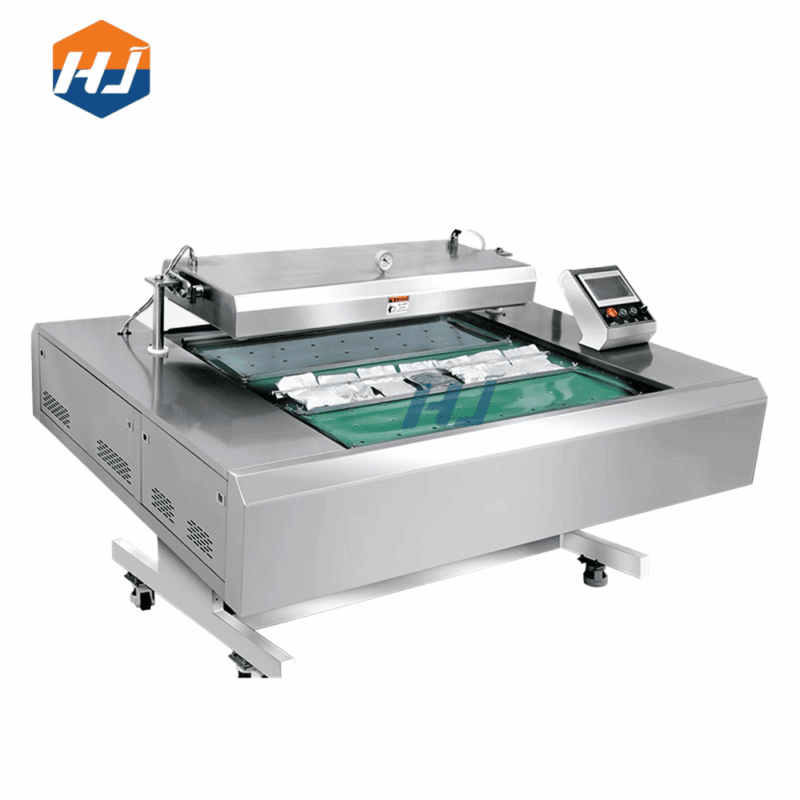

Soy protein extruder/Artificial meat machine/tofu skin machiner

The Tofu Skin Machine is an automated equipment specially designed for efficient production of vegetarian. Steak, plant-based meat products, etc. It can simultaneously complete processes such as tofu skin forming and high-temperature.

Shaping, and can be integrated with other processing lines to produce diverse vegetarian products. From raw material input to finished product output, it only takes about 5 minutes, and each machine requires only 1 operator, significantly reducing labor costs and increasing production capacity. With fully automated process control, it features core advantages of high efficiency, energy saving, small footprint, zero noise, and zero pollution.

Applications:

- Specifically designed for producing vegetarian steak (plant-based meat) and tofu skin, supporting various flavorings like braising, smoking, five-spice, and spicy.

- Widely used in soybean product processing plants, food processing factories, prepared food production lines, and soybean product stores.

Features:

- Digital control panel allows easy operation via button adjustment.

- Internal and external heating via spiral friction generates heat, promoting better product shaping.

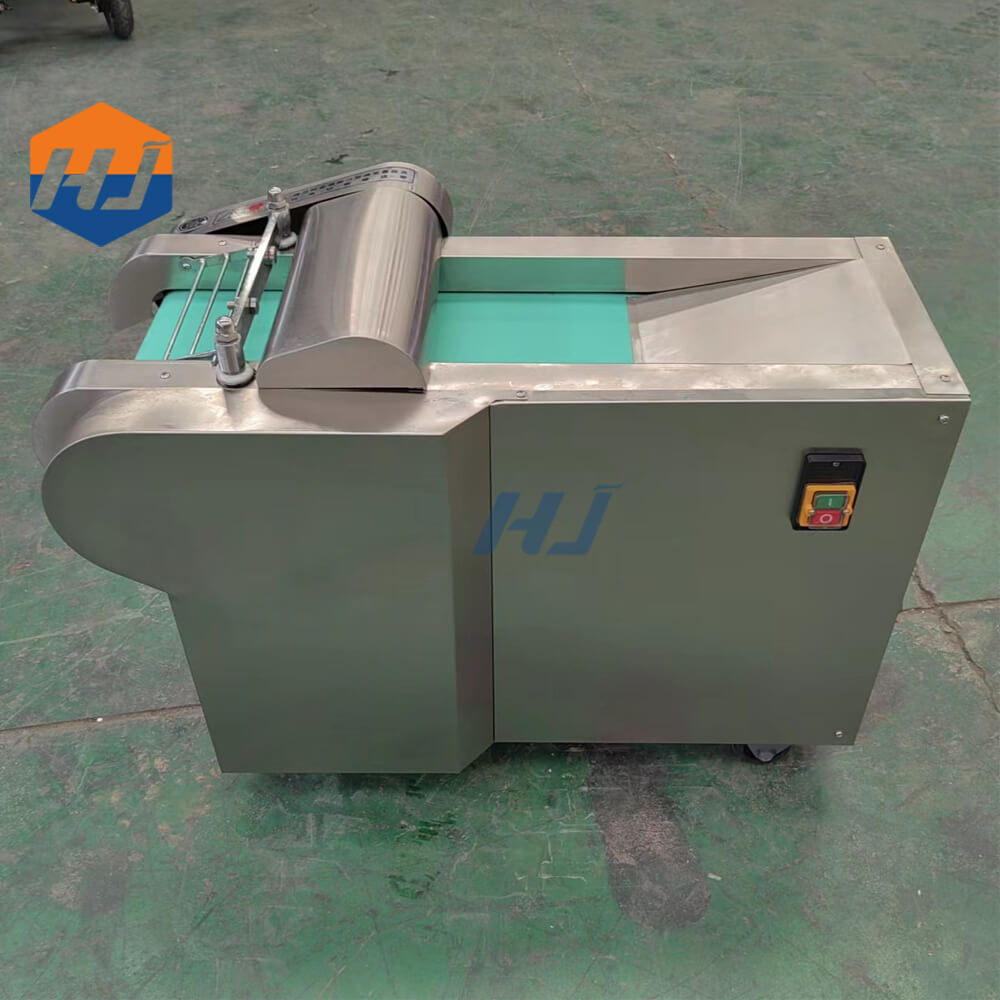

Tofu skin shredder

This machine is specifically designed for shredding bean curd sheets into uniform strips, with adjustable cutting widths. It also serves as a versatile vegetable processor, capable of slicing, shredding, and dicing a wide range of vegetables such as radishes, potatoes, cucumbers, cabbage, and celery.

When in operation, ingredients are fed onto the conveyor belt and transported smoothly to the high-speed continuous cutting blades, ensuring efficient and precise processing in one seamless cycle.

Twisting machine

The twisting machine, also known as the bean gluten twister or spicy strip forming machine, is a core shaping device in the production line of leisure soybean products such as spicy strips and vegetarian gluten strips. Its primary function is not cutting, but rather using mechanical rotation and traction to twist single, strip-shaped, cooked bean gluten into unique spiral or braided shapes, which are then cut into segments.