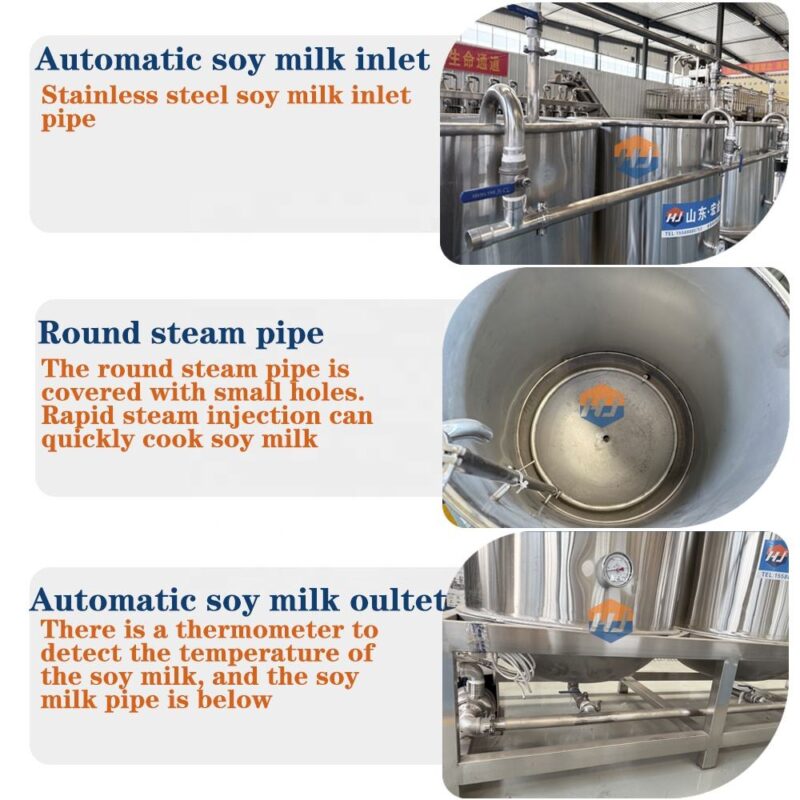

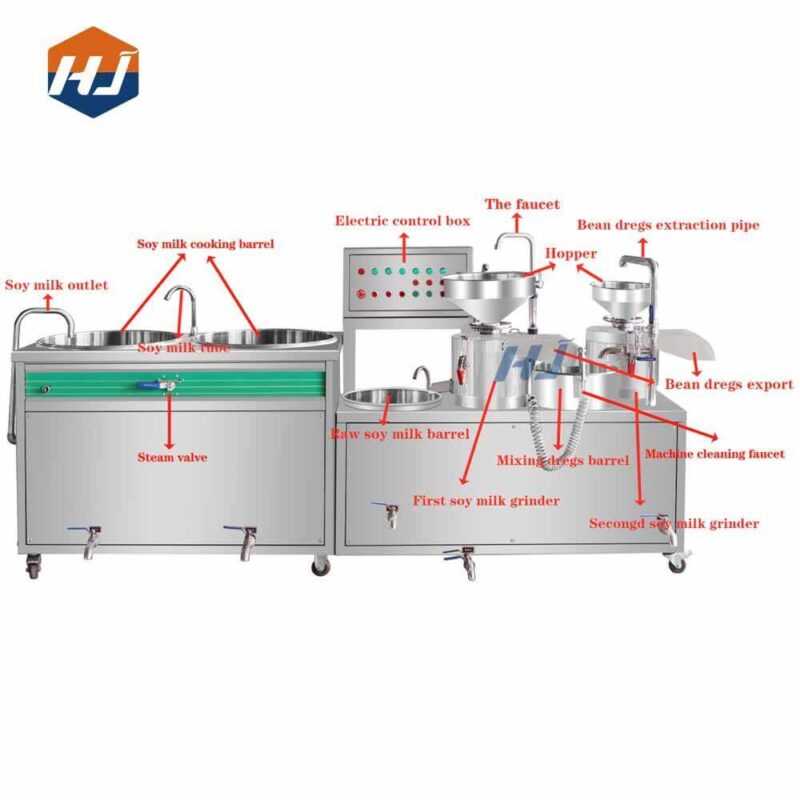

The automatic soymilk cooking equipment consists of several interconnected cooking tanks, each equipped with steam heating pipelines. Steam is injected into the system to rapidly and evenly heat the soy milk, ensuring complete and efficient cooking. The open-top design allows operators to easily monitor the cooking process, add ingredients, or assist with manual operations when needed.

With multiple tanks working in sequence, the system provides sectional heating, improving thermal efficiency and achieving a more thorough cooking process. This ensures consistent and high-quality soy milk for producing tofu, tofu sheets, dried tofu, and other soy products.

Benefits of the Machine:

Uniform Steam Heating: Prevents scorching and ensures even cooking throughout the tank.

High Production Efficiency: Multiple tanks allow continuous and large-volume processing.

Operator-Friendly Open Design: Easy to monitor, stir, and adjust during operation.

Thorough Soy Milk Cooking: Enhances the texture, smoothness, and stability of final soy products.

Easy Cleaning & Maintenance: Open-top tanks reduce residue buildup and simplify cleaning.

Flexible Configuration: The number of tanks can be customized according to production needs.